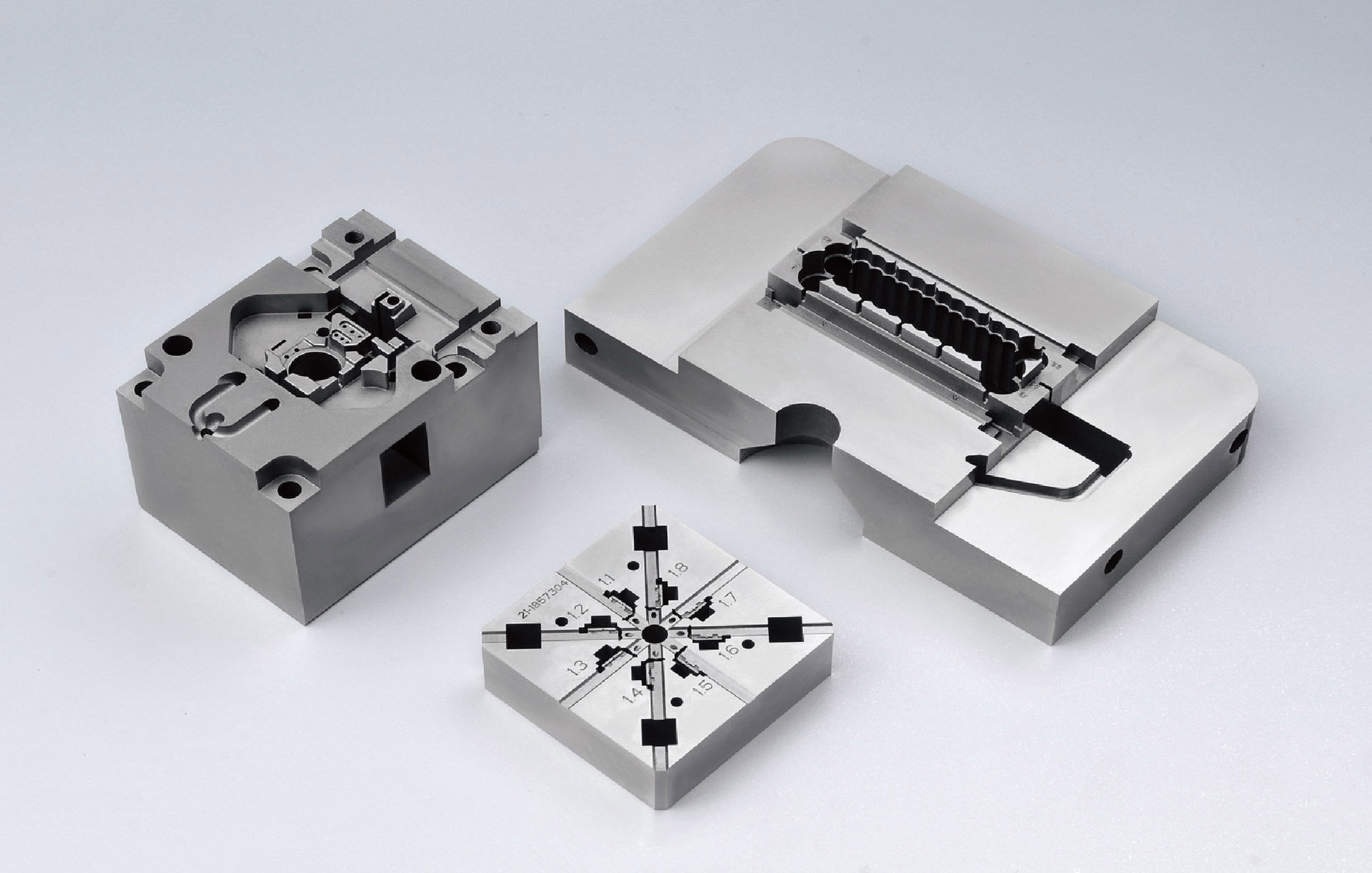

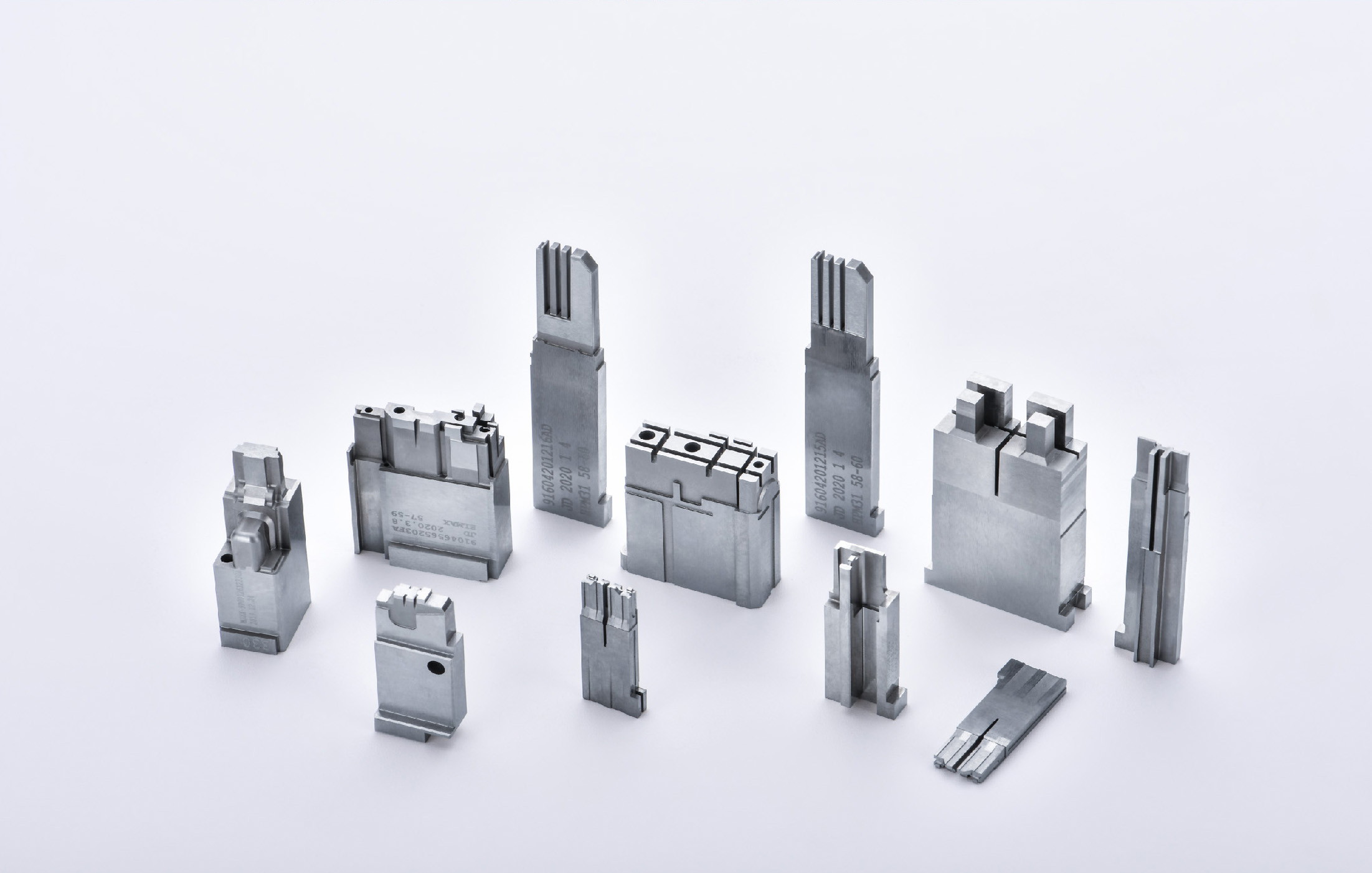

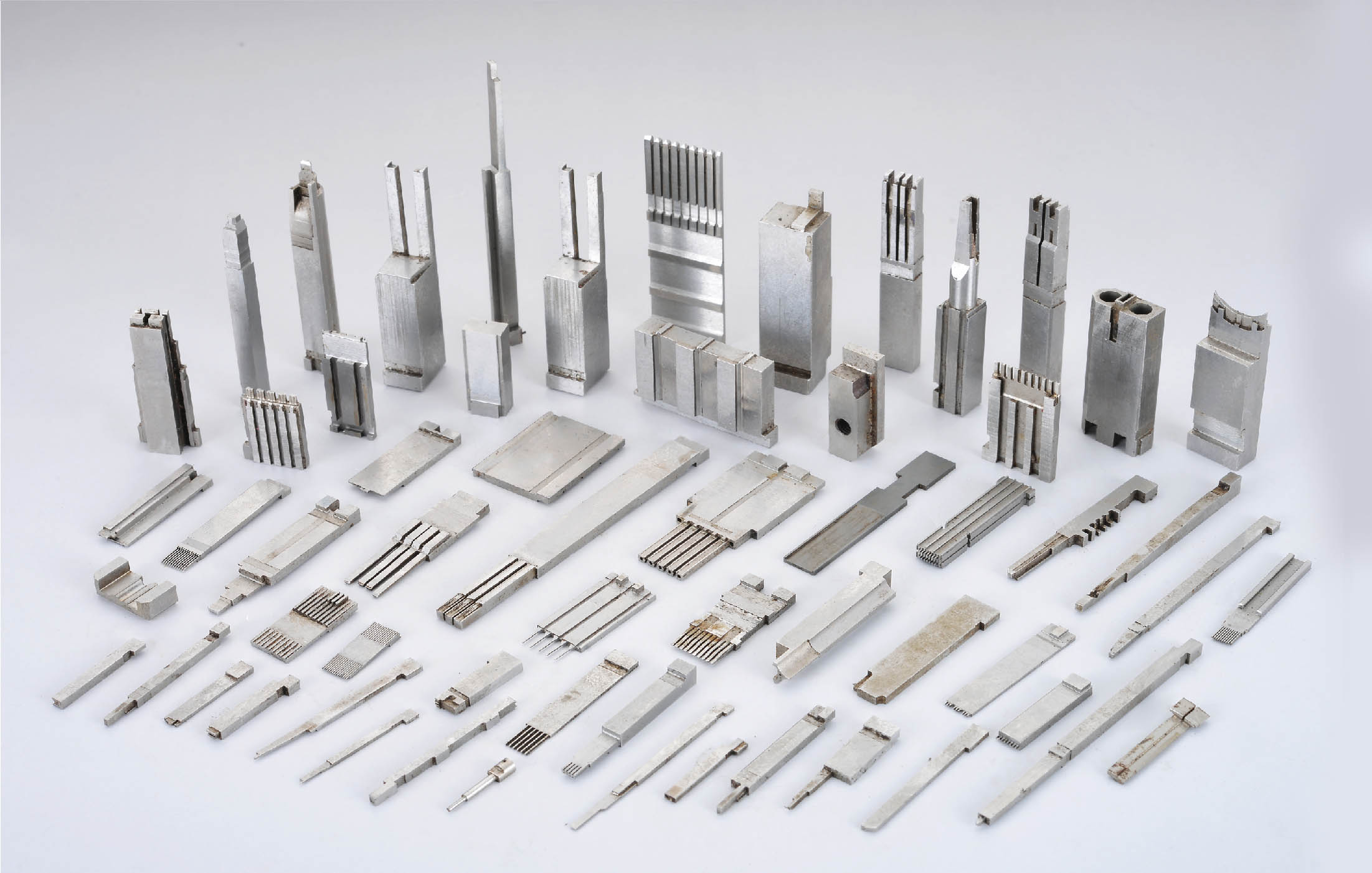

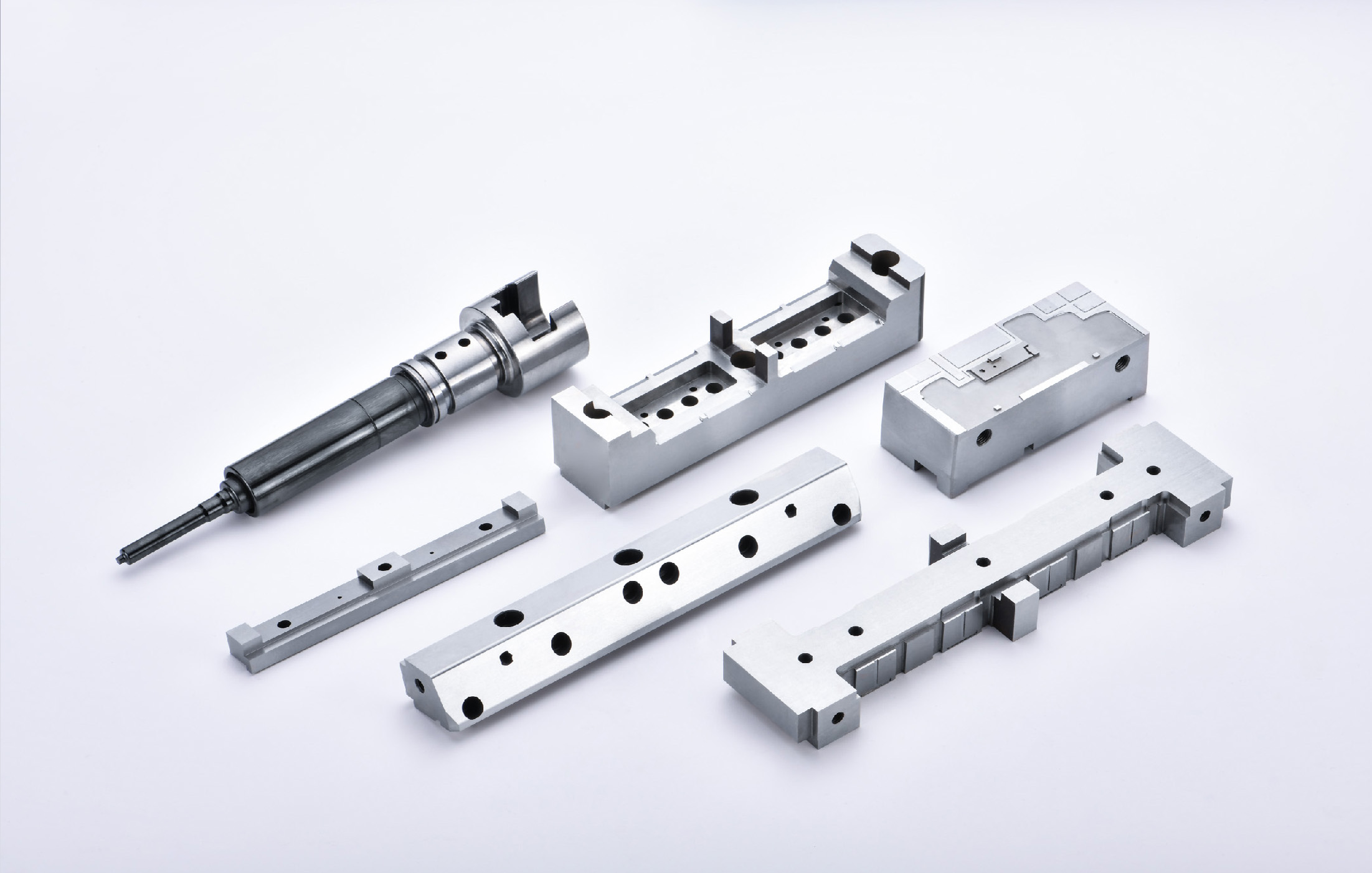

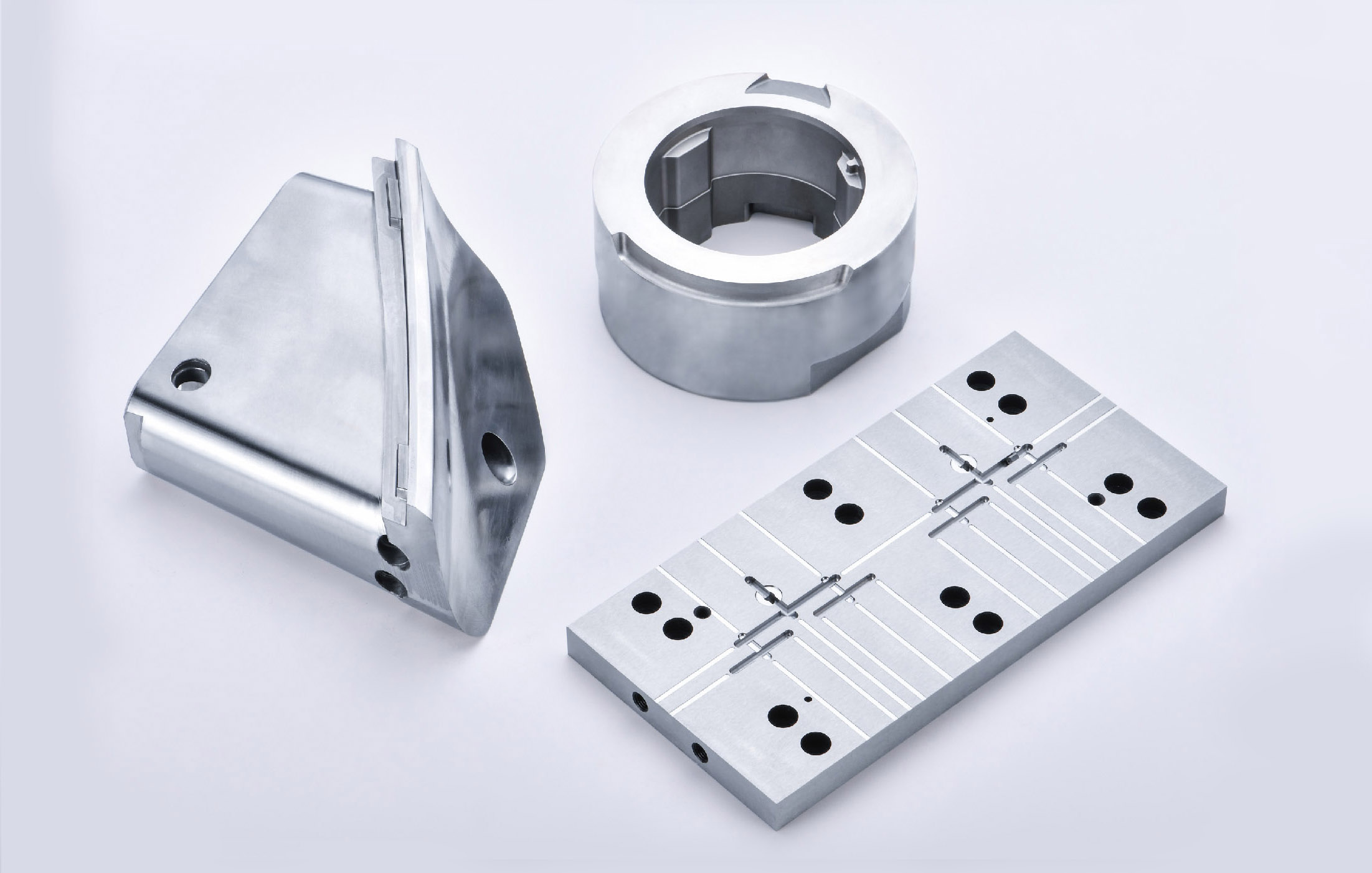

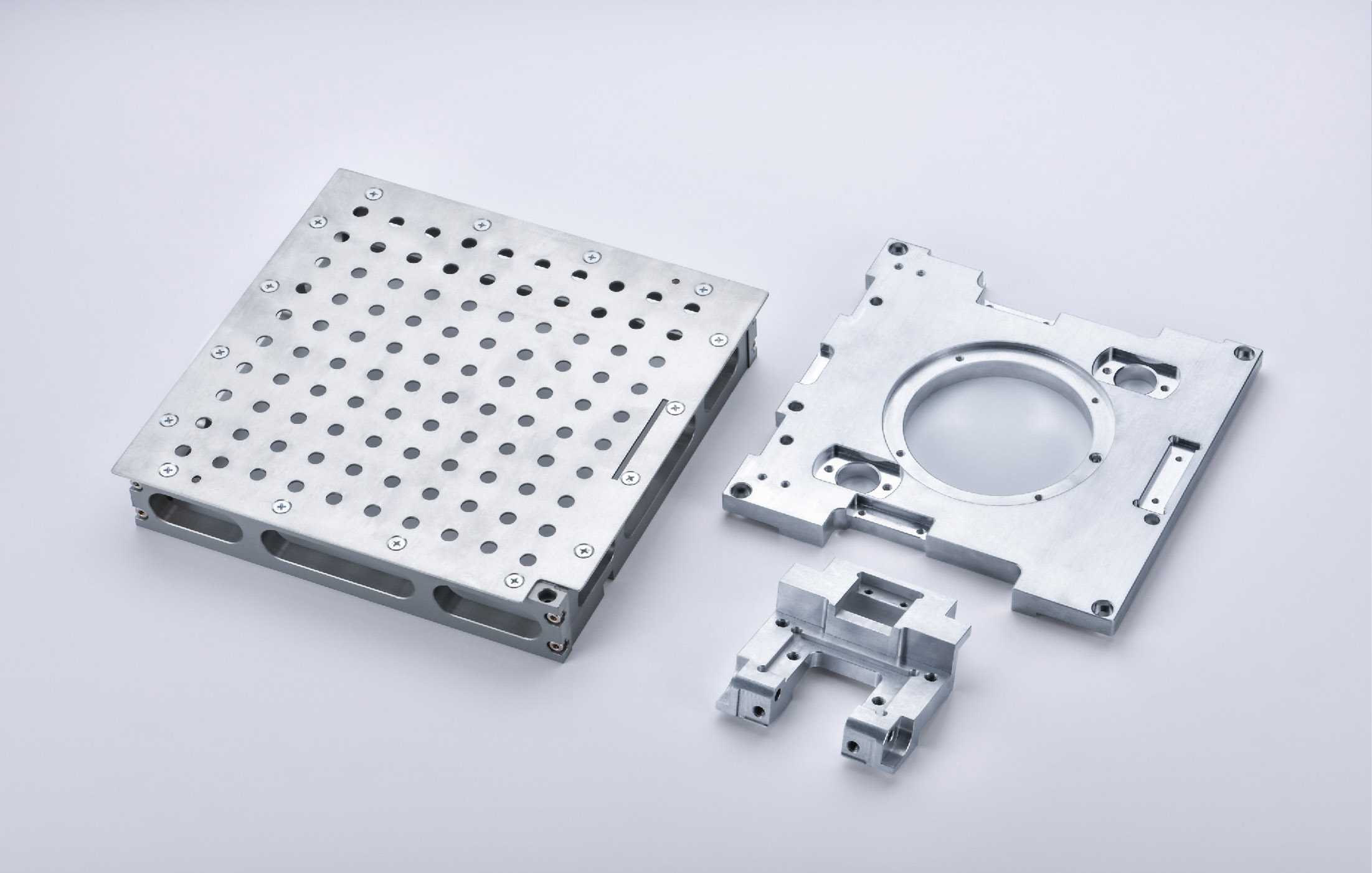

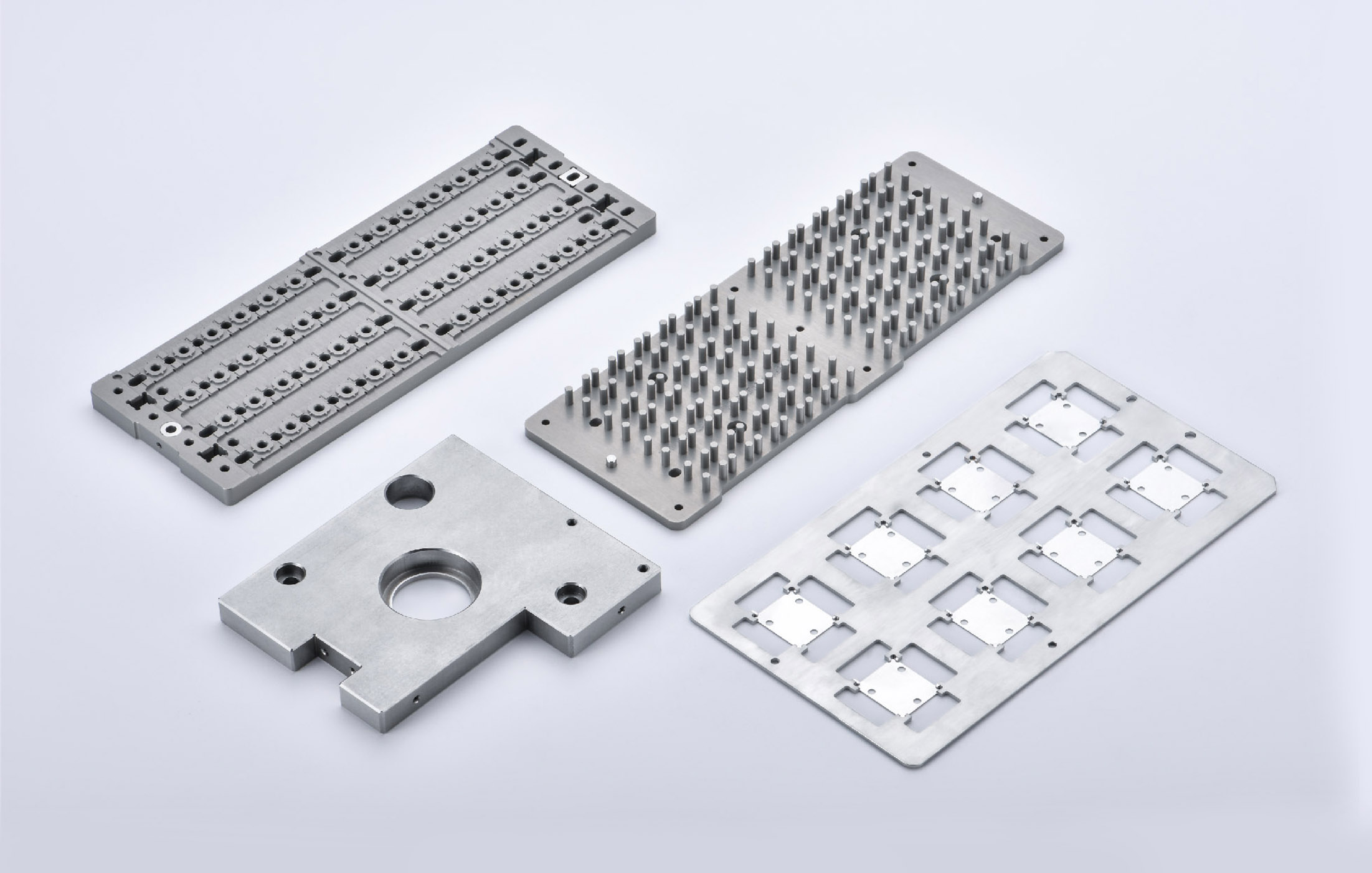

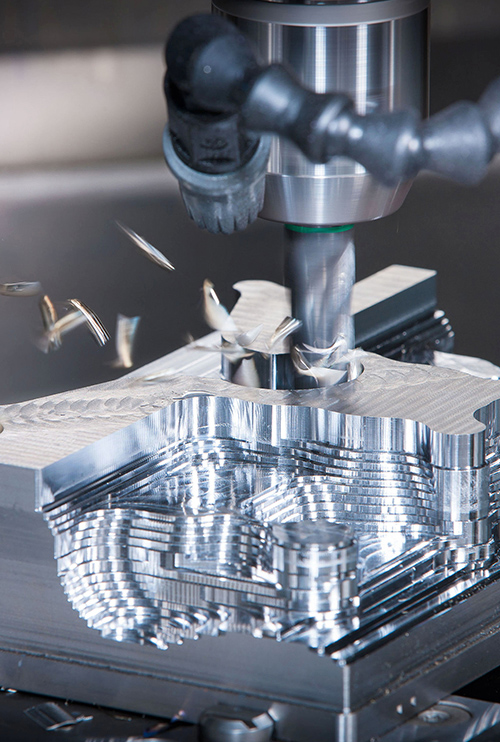

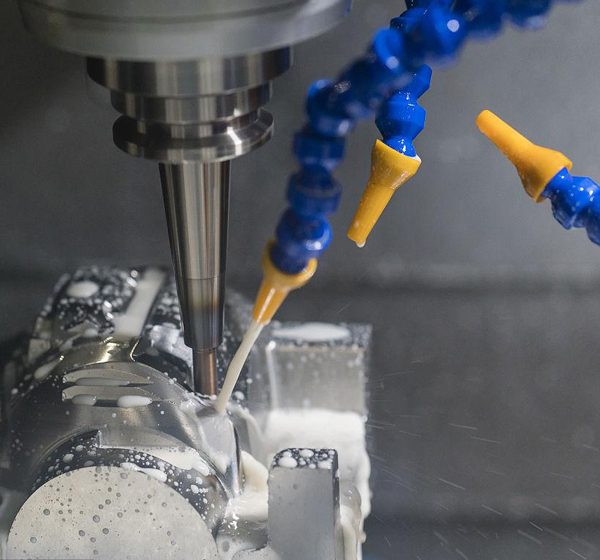

Fair Shine Industrial (Hong Kong) Co., Limited is a high-tech enterprise specializing in the production of high-precision mold parts for cosmetics, medical applications, bottle cap packaging, automotive shells, die-casting molds, and hot runner systems. Our products are widely used in injection molds, die-casting molds, daily chemical packaging molds, medical packaging molds, as well as industries like new energy, aerospace, digital electronics, automotive, and home appliances. We can flexibly meet the diverse and small-batch needs of clients across these sectors.

In particular, with our expertise in multi-cavity injection molds, we have gained strong customer praise. By producing various precision gauges and matching them with our advanced inspection equipment, we ensure the uniform size and interchangeability of core parts, enhancing product consistency and reliability across all our mold components.