Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

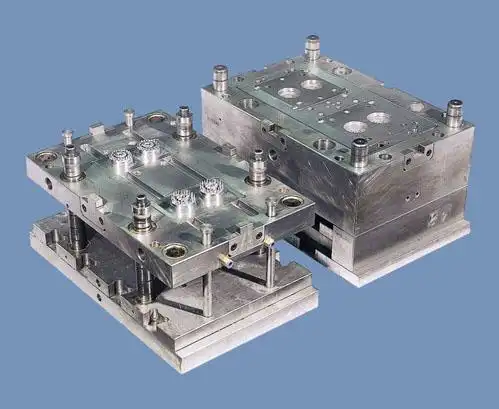

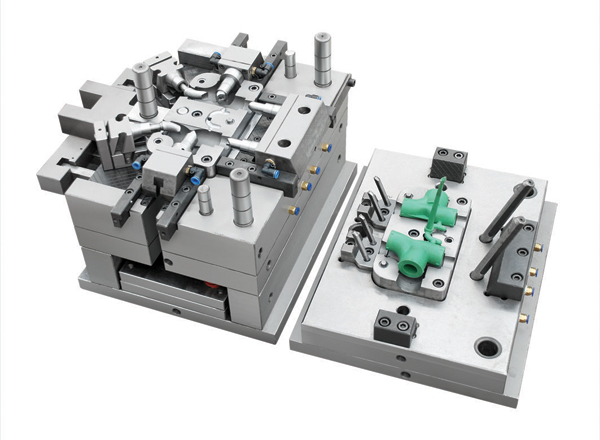

Custom-auto-connector-mold-insert | |

Product Name | Custom-auto-connector-mold-insert |

Brand Name | Fair Shine |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Dongguan Huixiang Mold Technology Co., Ltd. was established in 2013. It is a manufacturing factory covering an area of 5,000 square meters integrating production and sales.

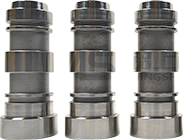

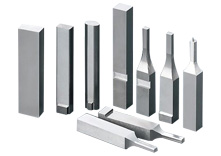

Mainly produces: SKD61, SKD11, DC53, SKH51, SKH-9, ASP23, M35, M42, tungsten steel T-type punch, A-type punch, three-level punch, parent punch, tooth punch, bevel punch Punch, guide punch, special-shaped punch (square, hexagonal, elliptical), needle gauge, contour screws, contour sleeves, positioning pins, lifting pins, round auxiliary devices, guide posts and bushings, support pins, flat Ejectors, sleeves, PIN pins, terminal mold inserts, connector mold inserts, hardware/plastic mold precision mold cores and other customized special shapes, automobile inspection tools, etc.

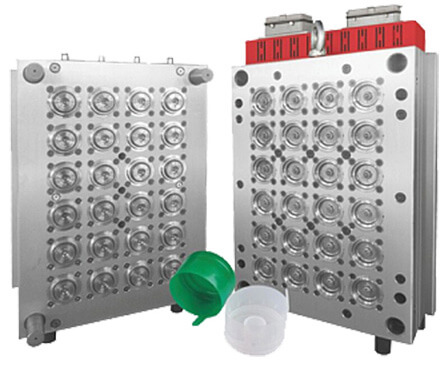

The main materials are imported from Germany and Sweden, and the performance is stable. The heat treatment is supported by professional manufacturers, and is equipped with advanced production equipment and a group of experienced professional and technical personnel to make the product's accuracy, performance, and service life even better. One chip, the service is More convenient! Especially in terms of various multi-cavity injection molds, by producing various precision inspection and metallurgy tools to match existing inspection equipment, the various types of chips produced by our company have uniform sizes and strong interchangeability, and have won unanimous praise from our customers.

1. Drilling die sets, beryllium bronze molds, diamond pins, positioning pins, countersunk hole pins, ejection pins, pins, connecting screws, material blocking shafts, blocking Customized mechanical parts such as material sleeves and bushings;

2 . Guide post guide bushing, GP auxiliary guide post, GP auxiliary guide bushing, SRP ball guide post guide bush, SGP sliding guide post guide bush, discharge plate guide post guide bush, TRP detachable guide post guide bush, independent guide post , non-standard guide posts and bushings and other cold stamping mold accessories; .

3. Non-standard customization of SKH51 thimbles, SKD61 thimbles, supporting pins, flat thimbles, shooting pins, cylinder pins, push tubes, imported material thimbles and cylinder cylinders;

4. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

5. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

6. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

7. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

8. Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds;

How to set the mold requirements for precision injection molding processing

Precision mold injection molding processing plants are usually completed through injection molding machines and molds, and the mold is the most important component. It will directly affect the quality of the final product, so injection molding processing usually has an impact on the accuracy of the mold. Extremely high request.

The following will give us a more detailed answer on several aspects of the mold accuracy requirements of precision injection molding processing plants.

1. It is very easy to understand the standard requirements of precision injection molding processing plants. If the size of the mold has large differences, the size errors of the products produced will naturally exist.

2. Requirements for surface roughness of precision injection molding processing plants. If the surface of the mold is not smooth and detailed, the products produced will be rough and need to be polished again or even directly scrapped. This will directly affect the company's work efficiency.

3. Density requirements of precision injection molding processing plants. Generally, the higher the density of the mold, the stronger its pressure-bearing capacity, and the less likely it is for the injection molding processing plant to deform. Therefore, the density of the mold must be selected carefully.

When processing plastic molds for precision injection molding, engineering plastic materials should be selected first. Engineering plastics that can be used for precision injection molding must use materials with high mechanical properties, stable dimensions, good creep resistance, and resistance to environmental stress cracking.

During the processing, the factors that affect precision injection molded products mainly come from the temperature of the mold, the control of the injection molding process, the change range of ambient temperature and humidity at the production site, and the annealing treatment of the acquired product.

Whether the injection mold design is reasonable or not will directly affect the shrinkage rate of the plastic product. Since the mold cavity size is calculated by adding the estimated shrinkage rate to the size of the plastic product, the shrinkage rate is determined by the plastic manufacturer or the engineering plastics manual. A recommended range of values, which is not only related to the gate form, gate position and distribution of the mold, but also to the crystal orientation (anisotropy) of the engineering plastic, the shape and size of the plastic product, the injection molding processing plant, and the gate. It is related to the distance and position of the mouth, and is closely related to the mold cooling distribution system.

The main factors that affect the shrinkage of plastics include thermal shrinkage, phase change shrinkage, orientation shrinkage, compression shrinkage and elastic recovery, and these influencing factors are related to the molding conditions or operating conditions of precision injection molded products.

The program control of the injection speed is to divide the injection stroke of the screw into 3 to 4 stages, and use the appropriate injection speed in each stage.

For example: slow down the injection speed when the molten plastic first passes through the gate, use high-speed injection during the mold filling process, and slow down the speed at the end of the mold filling. This method can prevent overflow, eliminate flow marks and reduce the number of finished products. residual stress, etc.

When filling the mold at low speed, the flow rate is stable, the size of the product is relatively stable, the fluctuation is small, the internal stress of the product is low, and the stress in each direction inside and outside the product tends to be consistent (for example, a polycarbonate part is immersed in carbon tetrachloride and used for high-speed injection molding) Parts with cracks are poured in the direction of the injection molding process, but those with low speed will not crack).

Under relatively slow mold filling conditions, the temperature difference of the material flow, especially the large temperature difference between the material before and after the gate, helps to avoid the occurrence of shrinkage cavities and dents. However, due to the longer filling time, it is easy for the parts to delaminate. And poor welding marks not only affect the appearance, but also greatly reduce the mechanical strength.

During high-speed injection, the material flow speed is fast. When the high-speed mold filling is smooth, the melt fills the cavity quickly, the material temperature drops less, and the viscosity drops less. Lower injection pressure can be used, which is a kind of hot material filling. The mold shape and high-speed mold filling can improve the gloss and smoothness of the parts, eliminate the seam line phenomenon and delamination phenomenon, have small shrinkage and depression, uniform color, and ensure the fullness of the larger parts of the parts.

However, it is easy for the product to become fat and blistered or yellow, or even burn and scorch, or cause difficulty in demoulding, or uneven mold filling. For high-viscosity plastics, it may cause melt rupture and cause cloud spots on the surface of the part. .

What issues should be paid attention to when manufacturing injection molds

It usually takes about a month to open an injection mold. Complex molds take longer. Usually when opening an injection mold, a detailed review is required. The mold can only be opened after approval. After opening the injection mold, the mold needs to be tested. The following items are required for injection mold manufacturing:

1. The cooling (water channel) in the mold is related to factors such as product size, shape, plasticity and pressure holding time.

2. The roughness of the mold cavity should reach "mirror level", otherwise the product will be difficult to demould, and when the product is ejected, the product will require too much power and will be easily damaged. There are standards for the roughness of positioning pins, clamping surfaces and other components

3. The plastic mold should be rigid, otherwise it will deform when the mold is kept under pressure, resulting in "flash". Choose a reasonable exhaust position and its control amount. Otherwise, the plastic is not filled and the product is "out of material."

4. The injection molding path should be selected reasonably so that the material reaches every place evenly (equal flow paths), and there should be enough storage space to replenish plastic during the shrinkage process. Moreover, the shrinkage coefficient of each material is different, and the mold has a reasonable shrinkage rate.

5. The mold and injection molding machine must be fixed in a reasonable and reliable manner to prevent accidents caused by displacement when the mold is closed. Disassembly is also very convenient. In addition, it is necessary to choose a reasonable demoulding method and select the appropriate position and number of ejector pins to ensure that the product is not damaged during the ejection process.

Is it difficult to make injection molds? It may be caused by these 5 problems!

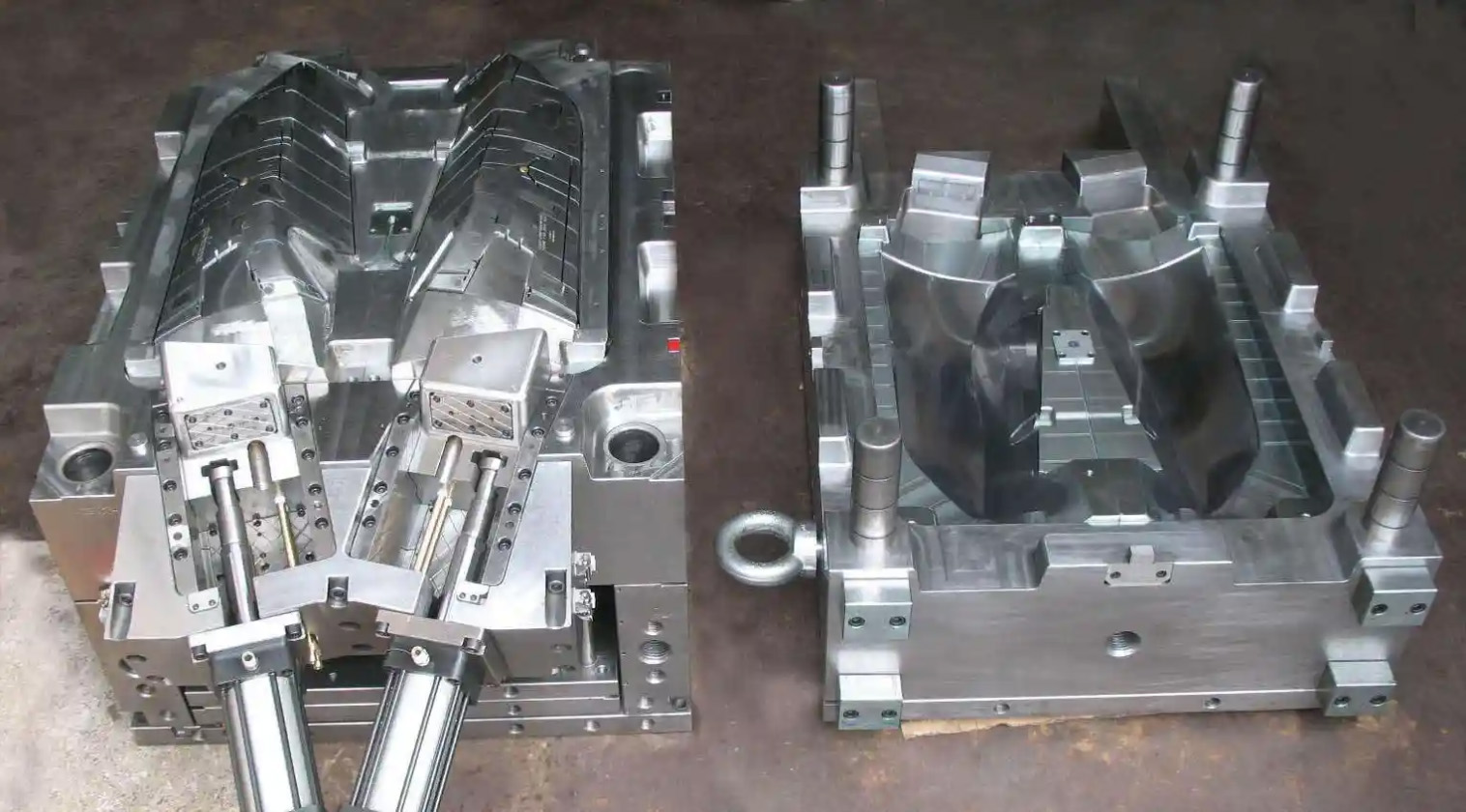

The cavity and core are three-dimensional.

The external and internal shapes of plastic parts are directly formed by the cavity and core. The processing of these complex three-dimensional profiles is relatively difficult, especially the processing of the blind hole inner molding surface of the cavity. If traditional processing methods are used, not only It requires workers to have high technical level, many auxiliary tools, fixtures, and tools, and the processing cycle is long.

High precision and surface quality requirements, long service life requirements

At present, the dimensional accuracy requirements of general plastic parts are IT6-7 and the surface roughness Ra0.2-0.1μm. The corresponding dimensional accuracy requirements of injection mold parts are IT5-6 and the surface roughness Ra0.1μm or less.

The roughness of the recording surface of the laser disk must reach the level of mirror processing of 0.02-0.01 μm, which requires the surface roughness of the mold to be less than 0.01 μm. Long-life injection molds are necessary to improve efficiency and reduce costs. At present, the service life of injection molds is generally required to be more than 1 million times.

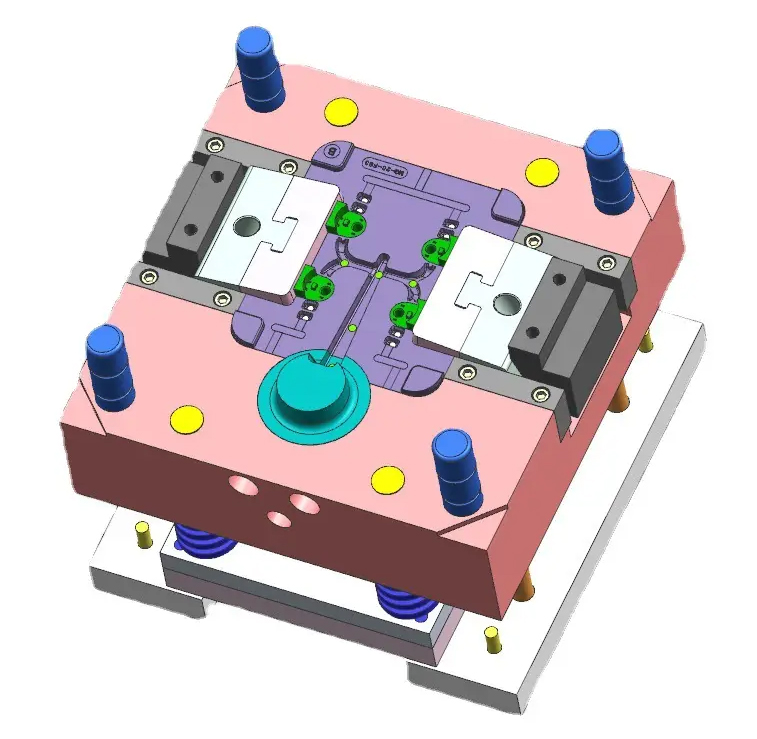

Precision injection molds need to use a mold base with high stiffness, increase the thickness of the template, and add support columns or tapered positioning elements to prevent the mold from deforming under pressure. Sometimes the internal pressure can reach 100MPa.

The ejection device is an important factor affecting the deformation and dimensional accuracy of the product, so the best ejection point should be selected to ensure uniform demoulding everywhere. High-precision injection molds mostly use inlaid or fully assembled structures in structure, which requires the processing accuracy and interchangeability of mold parts to be greatly improved.

The process flow is long and the manufacturing time is tight.

For injection molded parts, most of them are matched with other parts to form a complete product, and in many cases, other parts have been completed, and the injection molded parts are eagerly awaiting the launch of the supporting parts. Because the shape or dimensional accuracy of the product is very high, and due to the different characteristics of the resin materials, repeated mold trials and corrections are required after the mold is manufactured, making the development and delivery time very tight.

Designed and manufactured in other places.

Mold manufacturing is not the final goal, but the user proposes the final product design. The mold manufacturer designs and manufactures the mold according to the user's requirements. In most cases, the injection production of the product is also done by other manufacturers. This results in a situation where product design, mold design and manufacturing, and product production are carried out in different locations.

Professional division of labor and dynamic combination.

Mold production batches are small and generally belong to single-piece production. However, molds require a lot of standard parts, ranging from mold bases to ejector pins. These cannot and cannot be completed by only one manufacturer alone, and the manufacturing process is complex, ordinary equipment and CNC Equipment usage is extremely uneven.

How much do you know about these five steps in the injection mold production process?

Injection mold manufacturing can be roughly divided into the following steps:

1. Process analysis of plastic products.

Before mold design, the designer should fully analyze and study whether the plastic product complies with the injection molding processing principle. Careful consultation with the product designer is required, and a consensus has been reached. This includes necessary discussions on the geometric shape, dimensional accuracy and appearance requirements of the product, and try to avoid unnecessary complexity in mold manufacturing.

2. Mold structure design.

A set of high-quality molds not only requires good processing equipment and skilled mold manufacturing workers, but also a very important factor is good mold design. Especially for complex molds, the quality of mold design accounts for 80% of the quality of the mold. %above. An excellent mold design is: on the premise of meeting the customer's requirements, the processing cost is low, the processing difficulty is small, and the processing time is short.

To achieve this, we must not only fully digest the customer's requirements, but also have an understanding of the injection molding machine, mold structure, processing technology, and the mold factory's own processing capabilities. Therefore, to improve the level of mold design, the following points should be achieved:

1. Understand every detail in the design of each set of molds, and understand the purpose of each part in the mold.

2. When designing, refer to similar previous designs, understand the conditions during mold processing and product production, and learn from the experiences and lessons learned.

3. Learn more about the working process of the injection molding machine to deepen the relationship between the mold and the injection molding machine.

4. Visit the factory to understand the process of processed products and understand the characteristics and limitations of each type of processing.

5. Understand the trial results and mold modifications of the molds you designed, and learn lessons.

6. Try to use previously successful mold structures when designing.

7. Learn more about the impact of water entering the mold on the product.

8. Study some special mold structures and understand the latest mold technology.

3. Determine the mold material and select standard parts.

When selecting mold materials, in addition to considering the accuracy and quality of the product, the correct choice must also be made based on the actual processing and heat treatment capabilities of the mold factory. In addition, in order to shorten the manufacturing cycle, existing standard parts are used as much as possible.

4. Parts processing and mold assembly.

In addition to providing the best structure and reasonable tolerances during design, the precision of the mold is also crucial for parts processing and mold assembly. Therefore, the selection of processing accuracy and processing methods plays an absolutely dominant role in mold manufacturing.

1. The manufacturing error of the mold is about 1/3

2. The error caused by mold wear is about 1/6

3. The error caused by uneven shrinkage of molded parts is about 1/3

4. The error caused by the inconsistency between the scheduled shrinkage and the actual shrinkage is about 1/6

Total error=(1)+(2)+(3)+(4)

Therefore, in order to reduce mold manufacturing errors, the processing accuracy should first be improved. With the use of CNC machine tools, this problem has been well controlled. In addition, in order to prevent errors caused by mold wear and deformation, when processing molds with higher precision requirements and larger product output, key parts such as the cavity and core should be quenched. In medium and large molds, in order to save materials and facilitate processing and heat treatment, the mosaic structure should be used as much as possible when designing the mold.

In order to solve the errors caused by uneven shrinkage of molded parts and inconsistencies between predetermined shrinkage and actual shrinkage, 1/3 of the product tolerance is generally selected as the manufacturing tolerance of the mold during mold manufacturing. The purpose is to leave a larger margin for the subsequent molding process. Large room for adjustment to account for errors caused by the molding process.

5. Trial mold.

A set of molds, from design to assembly, only completes 70% to 80% of its entire manufacturing process. The error caused by the inconsistency between the scheduled shrinkage and the actual shrinkage, the smoothness of demoulding, the cooling effect, especially the impact of the size, position, and shape of the gate on the accuracy and appearance of the product must be tested through mold trials. Therefore, mold trial is an indispensable step to check whether the mold is qualified and to select the best molding process.

Our Services

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

Our adavanges

1. Clean and tidy workshop.

2.Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or according

to customer's requirement . It takes about 3-5 days to arrive your front

door, and proof of shippments are provided with a shipping or tracking

number. And we ship by occean shippment for larger quantity items,

it will be economic for customers.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang