Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

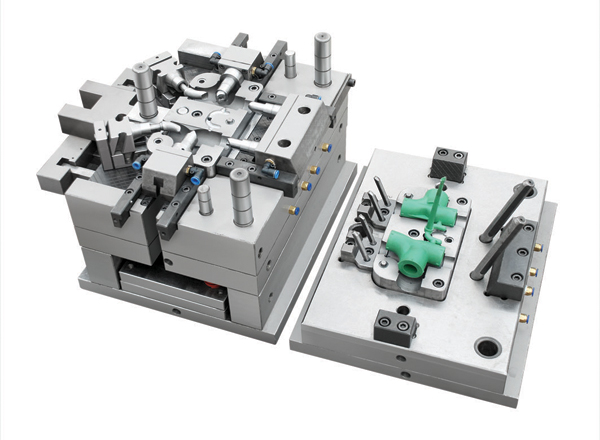

Custom-made-precision-auto-connector-mold-inserts | |

Product Name | Custom-made-precision-auto-connector-mold-inserts |

Brand Name | Fair Shine |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Dongguan Huixiang Mold Technology Co., Ltd. specializes in the production and wholesale of: high-precision TRP outer guide post components, high-precision SRP outer guide post components, ordinary ball TRP outer guide posts, ordinary ball SRP outer guide posts, stripper plate A-TRP terminals Mold guide post Assembly, stripper plate T-TRP terminal mold guide post Assembly, GP precision inner guide post, GAGB precision inner guide bushing, plastic-based steel ball sleeve, copper ball bushing, SGP sliding guide post, guide post for MRP mold base , Ball independent outer guide post, discharge plate inner guide post, discharge plate inner guide sleeve, graphite copper sleeve, miniature ball guide assembly, guide pin, standard T punch, domestic mold spring, imported alloy spring, nitrogen gas spring.

Processing: A company specializing in the production and processing of various non-standard guide posts, guide bushings, and other products.

The factory has a complete and scientific quality management system. Dongguan Huixiang Mold Technology Co., Ltd. has been recognized by the industry for its integrity, strength and product quality. Friends from all walks of life are welcome to visit, provide guidance and negotiate business!

1.Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds;

2. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

3. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

4. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

5. Bushings, die inserts, lower molds, CNC Customized standard and non-standard precision stamping mold accessories such as concave molds, special-shaped bushings, contour sleeves, floating pins, cross pin floating pins, guide lifting pins, tungsten steel punches, etc.;

6. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

7. Guide pins, positioning pins, stoppers Standard and non-standard customization of high columns, limit columns, etc.;

8. Non-standard customization of SKH51 thimbles, SKD61 thimbles, supporting pins, flat thimbles, shooting pins, cylinder pins, push tubes, imported material thimbles and cylinder cylinders;

Our Services

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

Our adavanges

1. Clean and tidy workshop.

2.Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or according

to customer's requirement . It takes about 3-5 days to arrive your front

door, and proof of shippments are provided with a shipping or tracking

number. And we ship by occean shippment for larger quantity items,

it will be economic for customers.

Process control of mold finishing

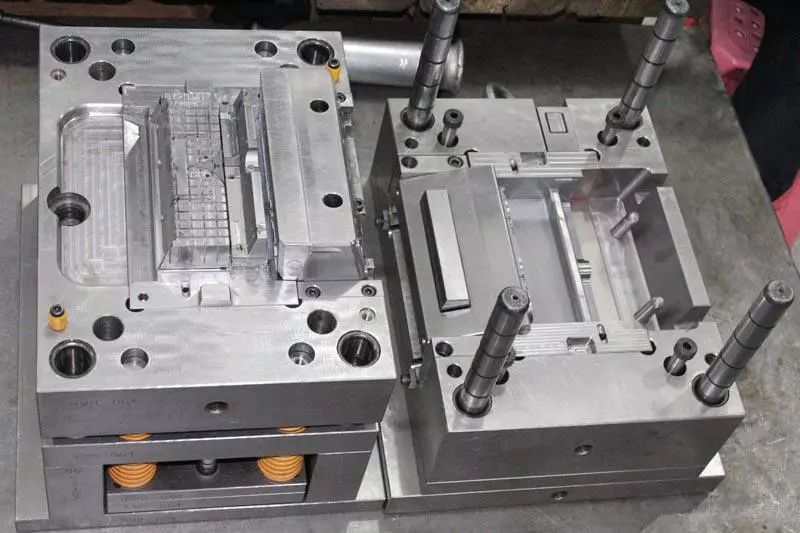

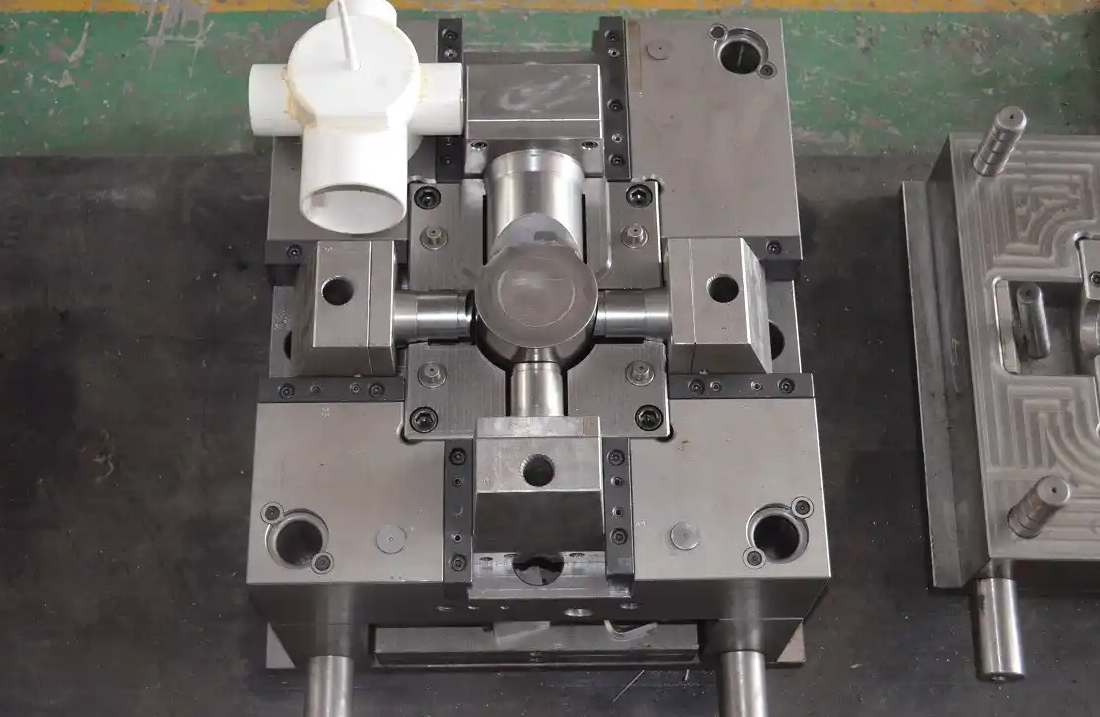

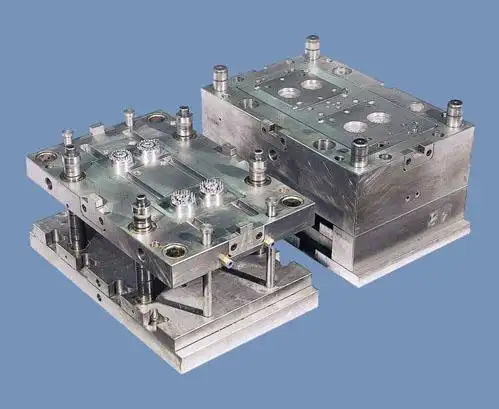

The general guiding idea for the processing of precision mold parts is to carry out adaptive processing for different mold parts, different materials, different shapes and different technical requirements. There are many selective solutions. However, achieving the best processing effect and economy through control of the processing process is our focus. According to the appearance and shape of precision mold parts, the parts can be mainly divided into three categories: shafts, discs, plates and molded heterogeneous parts. The process of these three types of parts is generally: rough machining-semi-finishing-(quenching, conditioning)-precision grinding-electrical machining-fitter trimming-assembly processing.

1. Heat treatment of precision mold parts

2. Precision mold parts grinding and processing

3. Electric processing of precision mold parts

4. Surface treatment of precision mold parts

The contents of molding surface treatment include no pores on the steel surface, uniform hardness, small differences in anisotropic properties, low inclusions, and places where stress concentration such as knife marks and grinding marks are left on the surface of the part during processing. Therefore, after the processing is completed, the surface of the parts needs to be strengthened, and hidden dangers in processing can be dealt with through mechanical polishing, bench grinding, and polishing. Blunt unnecessary edges, sharp corners, and openings of the workpiece. Generally, there will be a modified hardened layer of about 6 to 10 μm on the electrically machined surface, which is gray-white in color. This layer is brittle and contains residual stress. The hardened layer must be fully eliminated before use. The method is to polish the surface and remove the hardened layer. To obtain high-quality polishing effects, the material, shape, hardness of the workpiece and the surface quality of the cutting process must be fully considered. High-quality polishing tools, high-quality polishing materials, correct polishing procedures, and rigorous personnel are necessary. Quality, good clean environment.

5. Assembly of precision mold parts

During the grinding and electrical machining processes, the workpiece will be magnetized to a certain extent and has weak magnetic force, which can easily absorb some small debris. Therefore, before assembly, the workpiece must be fully demagnetized and the surface cleaned with ethyl acetate.

During assembly:

(1) First understand the assembly drawing and assemble various parts;

(2) List the assembly sequence of each component;

(3) Check the dimensional accuracy of each component and clarify the coordination requirements;

(4) ) Get the required tools, and then start assembling the mold;

(5) First install the guide pillars, guide sleeves, and cavity forming block components of the mold base; (6) Combine the template with the punch and concave mold, and add a trace amount Adjust the position of each plate;

(7) Open and close the mold to check whether the mold action is reliable.

What should we pay attention to in the process flow of hardware precision mold processing?

1. Bottom surface processing, processing volume guaranteed;

2. Casting blank benchmark alignment, 2D and 3D profile margin inspection;

3. Rough machining of 2D and 3D profiles, and machining of non-installation and non-working planes (including safety platform surface, buffer installation surface, pressure plate plane, and side reference plane);

4. Before semi-finishing, the correct accuracy of the side reference plane must be found;

5. Semi-finishing of 2D and 3D profiles, and finishing of various installation working surfaces (including limit block installation surface and contact surface, insert block installation surface and backrest surface, punch installation surface, scrap cutter installation surface and backrest surface , spring mounting surface and contact surface, various stroke limit working surfaces, wedge mounting surface and backrest surface), semi-finishing various guide surfaces and guide holes, leaving a margin for finishing the process reference hole and height reference surface, and recording data;

6. Inspect and review the processing accuracy;

7. Fitter and inlaying process;

8. Before finishing, align the datum plane of the process datum hole and check the insert allowance;

9. Finishing 2D and 3D profiles, side punching profiles and hole locations, precision mold processing technology reference holes and height benchmarks, finishing guide surfaces and guide holes;

10. Inspect and review the processing accuracy of hardware molds.

Things to note:

1. The process preparation should be concise and detailed, and the processing content should be expressed numerically as much as possible;

2. Special emphasis should be placed on the key and difficult points of processing;

3. The processing parts need to be combined and the process clearly expressed;

4. When the insert needs to be processed separately, pay attention to the process requirements for processing accuracy;

5. For the insert parts that need to be processed separately after combined processing, the benchmark requirements for separate processing of process installation during combined processing;

Spring is the most easily damaged in precision mold processing, so it is necessary to choose mold springs with long fatigue life.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang