Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

Custom molds for metal | |

Product Name | Custom molds for metal |

Brand Name | Fair Shine |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC50~64) |

Hardness | Depends on material(HRC50~64) |

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Dongguan Huixiang Mold Technology Co., Ltd. is a modern enterprise integrating R&D, manufacturing, sales and service. Its main products include: high-precision mold ejector pins, sleeves, support pins, flat ejector pins, punch pins, guide posts and guide bushes, We provide standard and non-standard accessories for hardware and plastic molds such as lifting pins, mold inserts, clamps, and jigs. We can also process all non-standard products in the mold machinery series and solve various technical problems in the mold machinery series on behalf of our customers. The products sell well in Guangdong, Jiangsu, and Zhejiang, Fujian and other provinces, exported to Europe, America, Japan, Southeast Asia and other countries, winning unanimous praise from customers!

Business philosophy: Careful design, precision manufacturing, excellent service, excellence, worrying about customers' needs, thinking about what customers want, and striving to provide perfect services to new and old customers with precise professionalism and a steady and down-to-earth work style!

Management philosophy: The excellent corporate culture of "customer-oriented and quality-oriented" makes us closely related and closely connected with our customers. "Products, technology, services and services" - the trinity business concept. Complete service supporting system. Let our customers have no worries!

Service concept: "Reputation first, quality first" is the company's eternal purpose, "first-class products and first-class services" is the direction of the company's efforts! Spiritual concept: We always strive to do our best!

1. Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds;

2. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

3. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

4. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

5. Bushings, die inserts, lower molds, CNC Customized standard and non-standard precision stamping mold accessories such as concave molds, special-shaped bushings, contour sleeves, floating pins, cross pin floating pins, guide lifting pins, tungsten steel punches, etc.;

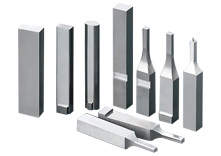

6. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

7. Guide pins, positioning pins, stoppers Standard and non-standard customization of high columns, limit columns, etc.;

8. Non-standard customization of SKH51 thimbles, SKD61 thimbles, supporting pins, flat thimbles, shooting pins, cylinder pins, push tubes, imported material thimbles and cylinder cylinders;

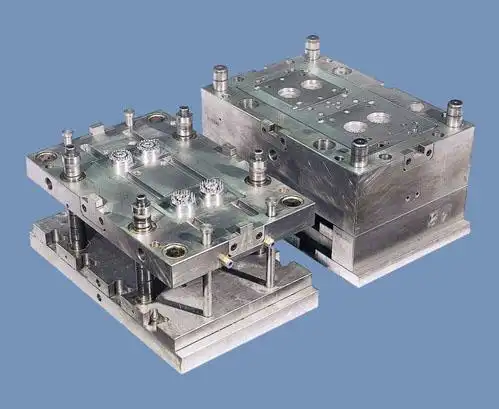

How to identify the quality of mold inserts?

Mold inserts with good quality and low price must come from professional manufacturers. Nowadays, reliable mold insert manufacturers can independently produce different types of mold inserts. With the increasing number of suppliers, it is difficult to choose High-quality mold inserts have become the first thing that buyers should pay attention to. As the saying goes, insiders look at the door and laymen see the excitement. The manufacturers of mold inserts remind you how to identify high-quality mold inserts.

How to identify the quality of mold inserts?

1. Different materials create different qualities.

The first element of a mold insert is to look at the material it is made of. Because the types of materials are different, their corresponding uses are also different. You can check whether the material meets the qualified standards by checking its component content and quality level. , you can rely on the test report information to confirm the quality of the mold insert. The better the quality is when the ingredients are sorted reasonably.

2. Observe the appearance, workmanship and production process of the product

Sometimes you can basically judge whether a mold insert is a good product simply by looking at its appearance. A smooth and undamaged appearance at least shows that the details have been handled well. Then there is a comparison of the production processes to see what manufacturers are using. Regardless of the level of production technology, high-quality mold inserts also have high requirements for the level of technology.

3. Refer to user reviews and industry reputation

User reviews are one of the ways to intuitively reflect the quality of mold inserts. If you communicate with people who have used them, you can basically know the service life and quality of mold inserts. You can also check the manufacturer's How is the reputation in the industry? Mold inserts produced by manufacturers with good reputation and influence can meet high-quality standards.

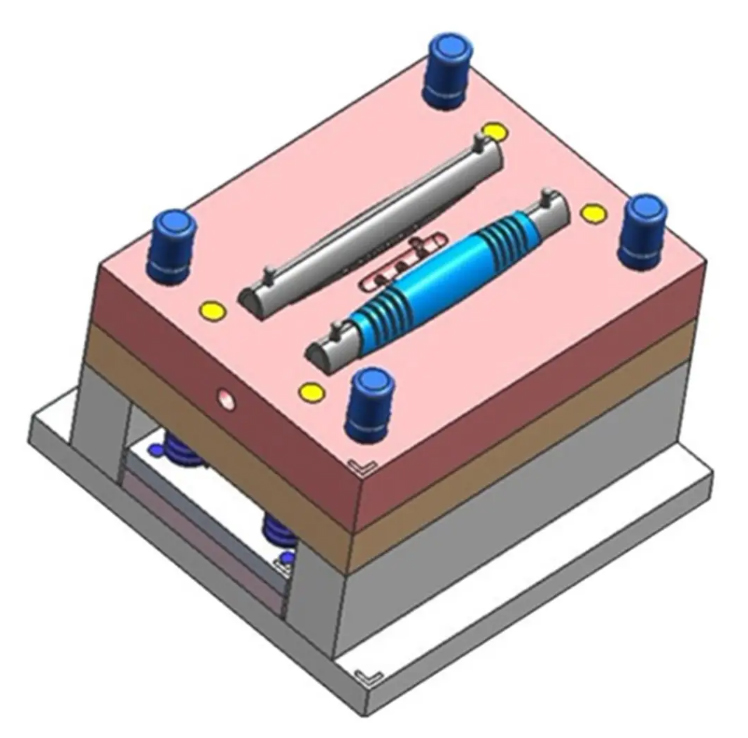

How much do you know about the classification of precision injection molds?

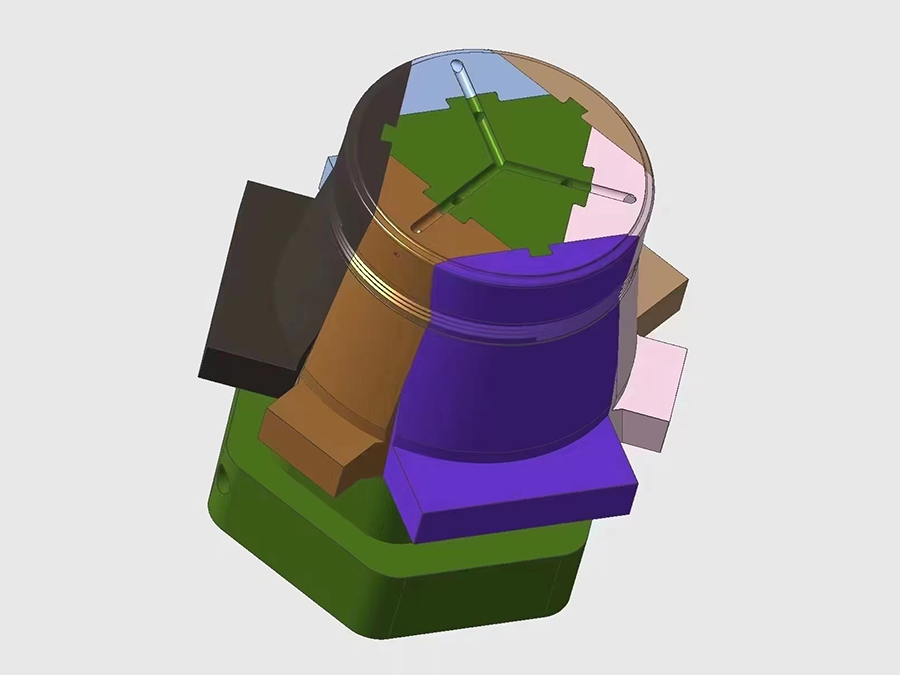

Precision injection molds can be divided into three categories according to the different types of pouring systems.

Hot runner mold, hot runner system, also known as hot runner system, mainly consists of hot runner sleeve, hot runner plate, and temperature control electrical box. Our common hot runner systems have two forms: single-point hot gate and multi-point hot gate. Single-point hot gate uses a single hot sprue sleeve to directly inject molten plastic into the mold cavity. It is suitable for plastic molds with a single cavity and a single gate; multi-point hot gate branches the molten material to various locations through a hot runner plate. The heat-separating sprue sleeve then enters the mold cavity. It is suitable for single-cavity multi-point feeding or multi-cavity molds. The structure of this type of mold is roughly the same as that of the fine nozzle. The big difference is that the flow channel is in one or more constant temperature The hot runner plate and hot spout have no cold material to demould. The runner and gate are directly on the product, so the runner does not need to be demoulded. This system is also called a nozzle system, which can save raw materials and is suitable for raw materials. When it is more expensive and has higher product requirements, it is difficult to design and process, and the mold cost is high.

Large nozzle mold: The runner and gate are on the parting line, and are demoulded together with the product when opening the mold. The design is quite simple, easy to process, and the cost is low, so more people use the large nozzle system to operate.

Thin nozzle mold: The runner and gate are not on the parting line, usually directly on the product, so it is necessary to design an additional set of nozzle parting lines. The design is more complex and the processing is difficult. Generally, the fine nozzle system is selected depending on the product requirements.

What are the factors that affect the precision mold processing structure?

1. Cavity layout. Determine the number of cavities and their arrangement based on the geometric structure characteristics of the plastic part, dimensional accuracy requirements, batch size, difficulty in mold manufacturing, mold cost, etc.

2. Determine the parting surface. The position of the parting surface should be conducive to mold processing, exhaust, demoulding and molding operations, as well as the surface quality of plastic parts, etc.

3. Determine the pouring system (shape, location, size of main runner, sub-runner and gate) and exhaust system (exhaust method, exhaust slot location, size).

4. Select the ejection method (ejector rod, ejection tube, push plate, combined ejection), and determine the undercut treatment method and core pulling method.

5. Determine the cooling and heating methods, the shape and position of the heating and cooling grooves, and the installation location of the heating elements.

6. Based on the mold material, strength calculation or empirical data, determine the thickness and outer dimensions of the mold parts, the outer structure and the positions of all connections, positioning and guide parts.

7. Determine the structural form of the main molded parts and structural parts.

8. Consider the strength of each part of the mold and calculate the working dimensions of the molded parts.

What should we pay attention to in daily maintenance of mold inserts?

Point 1: Check whether there is any foreign matter in the card slot

The mold insert will sink after long-term use. Once you find this phenomenon, you have to open it and see if there are any foreign objects in the slot of the mold insert to confirm the cause of the sinking. If there is If so, it must be cleaned up immediately.

Point 2: Check for cracks and damage at corners

Mold inserts will inevitably encounter bumps during use. You cannot turn a blind eye to some small bumps. Regular comprehensive inspections must be carried out. You must know that cracks and damage will affect the normal function of the mold inserts, and timely repairs can avoid them. .

Point 3: Keep the gap clean

Since lubricating oil is added to the mold insert when it is used, if the oil stains remain in the gap for a long time after use, it will make the movement of the mold insert less flexible. Therefore, if there are oil stains, special cleaning agents must be used to clean them. Clean and blow dry.

Point 4: Frequently moved parts need lubrication

One of the major advantages of mold inserts is to prevent mold damage. For frequently moving parts, add some lubricating oil to avoid jamming and control the wear range in a timely manner.

Our Services

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

Our adavanges

1. Clean and tidy workshop.

2.Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or according

to customer's requirement . It takes about 3-5 days to arrive your front

door, and proof of shippments are provided with a shipping or tracking

number. And we ship by occean shippment for larger quantity items,

it will be economic for customers.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang