Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

Plastic bottle cap mold | |

Product Name | Plastic bottle cap mold |

Brand Name | Fair Shine |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

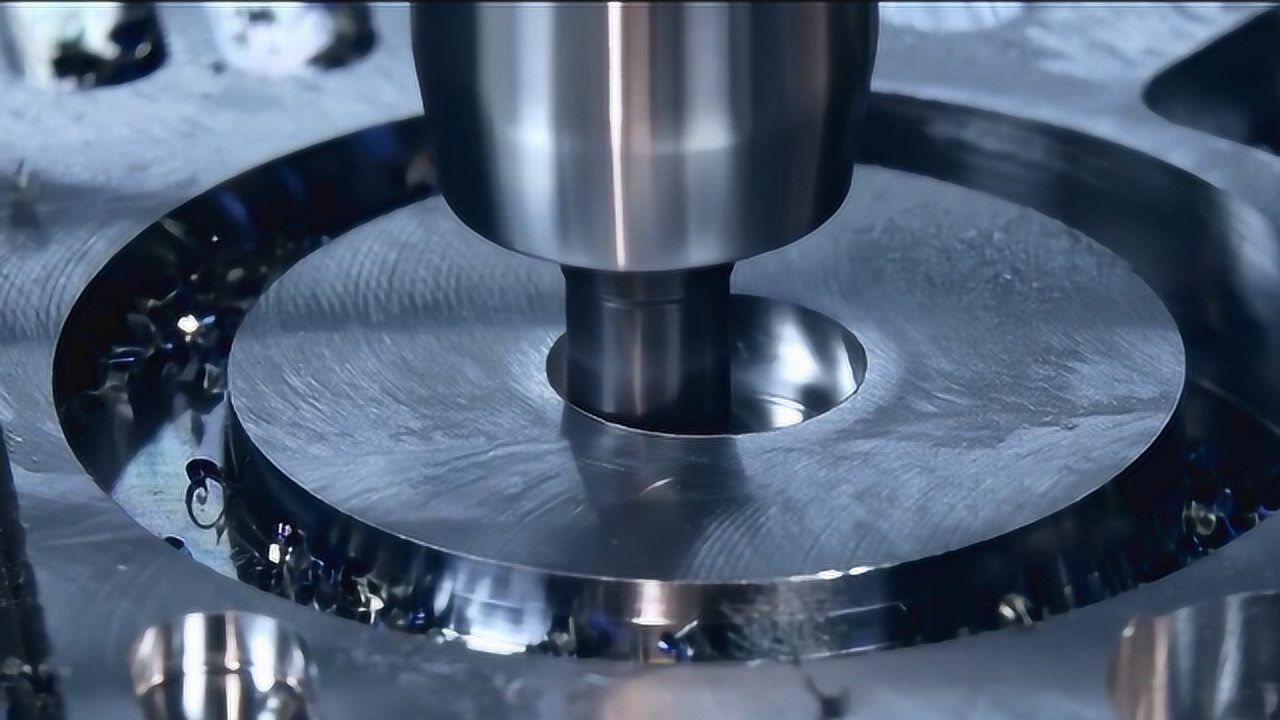

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Applicable mold types | Plastic mold |

1. Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds;

3. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

3. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

4. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

5. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

6. Bushings, die inserts, lower molds, CNC Customized standard and non-standard precision stamping mold accessories such as concave molds, special-shaped bushings, contour sleeves, floating pins, cross pin floating pins, guide lifting pins, tungsten steel punches, etc.;

7. Drilling die sets, beryllium bronze molds, diamond pins, positioning pins, countersunk hole pins, ejection pins, pins, connecting screws, material blocking shafts, blocking Customized mechanical parts such as material sleeves and bushings;

8 . Guide post guide bushing, GP auxiliary guide post, GP auxiliary guide bushing, SRP ball guide post guide bush, SGP sliding guide post guide bush, discharge plate guide post guide bush, TRP detachable guide post guide bush, independent guide post , non-standard guide posts and bushings and other cold stamping mold accessories;

Plastic bottle cap mold

Plastic bottle cap injection mold design

First, a brief overview of the role of plastic molds in the social field and its future development direction is given, and the importance of mold design is pointed out. Then perform process analysis based on the workpiece drawing, and then determine the design plan, calculate the size of the working part of the mold, and design the working parts; then select each standard component according to the design requirements, and then design the general assembly drawing of the mold. In design, the most important things are the determination of the design plan, the calculation and selection of blanks, and the design of working parts. This is the key to design. Whether these designs are correct or not is directly related to the cost and whether the designed mold can work normally.

Bottle cap mold is a special mold used to produce various plastic bottle caps. It usually consists of multiple parts, including lower template, upper template, mold core, mold base and upper cover, etc. These components play an important role in the mold design and manufacturing process.

The working principle of the bottle cap mold is similar to the process of producing plastic bottle preforms. It is mainly divided into four steps: lower template closing, blister forming, product forming and mold opening. After the lower template is closed, a complete mold space will be formed. The heated plastic is sucked into the blister hole of the upper template through injection molding. As the air pressure decreases, the plastic will be compressed and formed. Finally, the mold is opened to complete a production cycle.

The design and manufacturing of bottle cap molds requires professional technology and equipment to ensure the accuracy, stability and durability of the mold. High-quality bottle cap molds can improve production efficiency, reduce production costs, and ensure the quality and appearance of bottle caps. Therefore, when choosing a bottle cap mold, you need to consider factors such as the material, structure, manufacturing process of the mold, and the reputation and experience of the manufacturer.

Plastic bottle cap molds are mainly used in multiple packaging industries such as edible oil, beverages, candy, and medicine. These molds are characterized by high quality, energy saving, high efficiency and long service life, and can produce bottle caps that meet uniform quality standards and caliber parameters.

Specifically, the application range of plastic bottle cap molds is very wide, including but not limited to the following fields:

Food packaging: Used to produce lids for various food containers, such as beverage bottle caps, sauce bottle caps, etc.

Beverage packaging: Produces bottle caps for carbonated drinks, juices and other beverages to ensure sealing and leakage resistance

Pharmaceutical packaging: In the pharmaceutical field, plastic bottle caps are used to package medicines, health products, etc. to ensure the hygiene and safety of the products.

Daily chemical products: Used to produce packaging lids for shampoo, shower gel and other daily chemical products.

In addition, plastic bottle cap molds also have the following advantages:

High Smoothness: Mold surface treatment technology ensures the cover is smooth and reduces friction and residue.

Low cost: Compared with bottle caps made of other materials, the production cost of plastic bottle cap molds is lower.

Durable and efficient: The mold has long service life, high production efficiency, and is suitable for mass production.

Customized service: Bottle cap molds of different sizes and shapes can be customized according to customer needs.

1. Let customers save more effort: Huixiang Technology Division can quickly provide customers with good products based on relevant information such as 3D bottle cap modeling, bottle cap samples or conceptual descriptions of bottle caps provided by customers. With more than 20 years of experience, solution.

2. Save time for customers: With many years of mold manufacturing experience, Huixiang Technology Division has prepared standard mold parts with complete specifications in advance. From the time the customer places an order, we can quickly find and match the corresponding mold parts for assembly. and production, and the strict quality control system has greatly improved the efficiency and quality of mold processing, and ultimately our delivery time can be greatly shortened.

3. Regular mold progress reports: In order to help customers better understand the order progress and arrange related matters, Huixiang Technology Division provides mold progress reports at least weekly.

4. Quick service response: Huixiang Technology Division has a complete mold production process, and every drawing and data is recorded in detail. Therefore, during later maintenance, our team can quickly find the final mold data and provide quick help.

5. Ready-made sample display: Before the mold is shipped, Huixiang Technology will simulate production in the production workshop to further test the stability of the mold. Customers only need to pay the cost to obtain the plastic cover produced at this stage. Huixiang Technology will ship these plastic caps together with the molds, so before officially using our molds, customers can display a large number of our high-quality finished bottle caps to their partners, which not only helps to promote the early development of cooperation between the two parties, but also Can bring products to market quickly.

Dongguan Huixiang Mold Technology Co., Ltd. specializes in manufacturing precision photoelectric shafts/threaded electrodes/pen model cores/cosmetic parts/precision inserts/cores/bushes and SKH51/SKD61 series barrel ejector mold accessories, etc.;

products are widely used in Optoelectronics/digital electronics/medical packaging equipment/pen making/cosmetic packaging/electrical appliances/automobiles/mechanical motor axis manufacturing and other fields. The company's advantageous products include processing of non-standard mold parts, processing of brass + graphite wear-resistant blocks, processing of high-strength brass + graphite guide posts and bushings, processing of stainless steel guide posts and guide bushes, processing of various non-standard inserts, precision Plastic mold parts processing, metal stamping mold parts processing, die-casting mold parts processing, daily cosmetics mold parts processing, self-lubricating plates, self-lubricating guide rails, self-lubricating guide posts and guide bushes, brass plus graphite wear-resistant block processing, high-strength yellow Copper plus graphite wear-resistant block processing, oil steel plus graphite wear-resistant block processing, cast iron plus graphite wear-resistant block processing, precision tooling and precision automated machinery parts and many other fields, we provide customers with comprehensive solutions for precision mold parts processing.

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

1. Clean and tidy workshop..

2.Strick and serious manangement, skilled and expericenced technicians..

3. Various raw material(imported and Chinese) to meet different needs of customers. 4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory. 6. You can use English or Japanese for cummunication.

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or accordingto customer's requirement . It takes about 3-5 days to arrive your front door, and proof of shippments are provided with a shipping or tracking number. And we ship by occean shippment for larger quantity items,it will be economic for customers.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang