Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

Hardware Mold Parts | |

Product Name | Hardware Mold Parts |

Brand Name | Fair Shine |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Dongguan Huixiang Mold Technology Co., Ltd. is a modern enterprise integrating R&D, manufacturing, sales and service. Its main products include: high-precision mold ejector pins, sleeves, support pins, flat ejector pins, punch pins, guide posts and guide bushes, We provide standard and non-standard accessories for hardware and plastic molds such as lifting pins, mold inserts, clamps, and jigs. We can also process all non-standard products in the mold machinery series and solve various technical problems in the mold machinery series on behalf of our customers. The products sell well in Guangdong, Jiangsu, and Zhejiang, Fujian and other provinces, exported to Europe, America, Japan, Southeast Asia and other countries, winning unanimous praise from customers!

Business philosophy: Careful design, precision manufacturing, excellent service, excellence, worrying about customers' needs, thinking about what customers want, and striving to provide perfect services to new and old customers with precise professionalism and a steady and down-to-earth work style!

Management philosophy: The excellent corporate culture of "customer-oriented and quality-oriented" makes us closely related and closely connected with our customers. "Products, technology, services and services" - the trinity business concept. Complete service supporting system. Let our customers have no worries!

Service concept: "Reputation first, quality first" is the company's eternal purpose, "first-class products and first-class services" is the direction of the company's efforts! Spiritual concept: We always strive to do our best!

1. Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds;

2. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

3. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

4. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

5. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

6. Bushings, die inserts, lower molds, CNC Customized standard and non-standard precision stamping mold accessories such as concave molds, special-shaped bushings, contour sleeves, floating pins, cross pin floating pins, guide lifting pins, tungsten steel punches, etc.;

8. Non-standard customization of SKH51 thimbles, SKD61 thimbles, supporting pins, flat thimbles, shooting pins, cylinder pins, push tubes, imported material thimbles and cylinder cylinders;

9 . Guide post guide bushing, GP auxiliary guide post, GP auxiliary guide bushing, SRP ball guide post guide bush, SGP sliding guide post guide bush, discharge plate guide post guide bush, TRP detachable guide post guide bush, independent guide post , non-standard guide posts and bushings and other cold stamping mold accessories;

Hardware mold accessories: the core cornerstone of industrial manufacturing

In the field of modern industrial manufacturing, hardware mold accessories are key components that support precision production and improve efficiency. From automobile manufacturing to consumer electronics, from home appliance production to aerospace, the performance of mold accessories directly affects the accuracy, quality and production costs of the product. This article will comprehensively analyze the core value of hardware mold accessories from technical characteristics, material selection, industry application and future trends.

1. Core classification and functions of hardware mold accessories

Punch and die

Function: It realizes the punching, forming and separation of metal sheets, and is the "sharp blade" of the mold.

Type: circular punch, special-shaped punch, composite die, etc. The edge angle and gap need to be designed according to the material thickness and shape. The function of guide column guide sleeve and positioning

components: Ensure mold clamping accuracy, reduce motion friction, and improve life.

Technical points: High wear-resistant materials (such as SUJ2 bearing steel) are used and combined with the circulation lubrication system, which can withstand hundreds of thousands of reciprocating movements. Application scenarios for springs and elastic components: used for unloading, ejecting and resetting, divided into compression springs, nitrogen springs, etc.

Advantages: The life of nitrogen springs is 5-10 times longer than that of metal springs, and is suitable for high-speed stamping equipment. The functions of the thimble and oblique wedge mechanism: realize the release of complex parts and su

2. Materials and process: dual requirements for precision and durability

Material selection:

High-speed steel (SKH series): suitable for high-hardness material punching, hardness up to HRC62-65.

Tungsten steel (tungsten carbide): It has wear resistance of three times that of high-speed steel and is often used in mass-produced molds.

Powder metallurgical materials: molded through 3D printing technology, complex structures can be customized to improve material utilization.

Processing technology: CNC precision machining: The five-axis linkage machining center achieves μ-level accuracy to ensure the fitting clearance of accessories.

Vacuum heat treatment: Through quenching + deep cooling treatment, the toughness and fatigue resistance are improved. Coating technology: PVD/CVD coatings (such as TiN, CrN) can extend their life by 30%-50%.

3. Industry applications: From basic manufacturing to high-end fields

Automobile manufacturing: Cover mold accessories must withstand high-strength steel (1500MPa) stamping, and the guide column guide sleeve must be equipped with a forced cooling system.

Consumer Electronics: Precision terminal mold accessories require RA≤0.2μm surface finish, and are cut and processed by slow-travel wire.

New energy field: Lithium battery electrode mold accessories need to be corrosion-resistant and adhesive-resistant, and beryllium copper alloy is used for material.

Medical devices: Micro-stent mold accessories require nano-scale processing accuracy and adopt fine electric spark process.

4. Future trends: intelligence and sustainability

Intelligent monitoring technology: Embedded sensors monitor accessories wear and temperature in real time, predict maintenance cycles, and reduce downtime losses.

Environmentally friendly materials: Biodegradable lubricating grease, chromium-free surface treatment process to reduce environmental burden.

3D printing and additive manufacturing: Integrated molding of complex structural accessories, shortening the delivery cycle by more than 50%, suitable for small batch customization needs.

Digital design platform: AI-based mold accessories selection system, which automatically matches materials and process parameters to improve design efficiency.

Our Services

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

Our adavanges

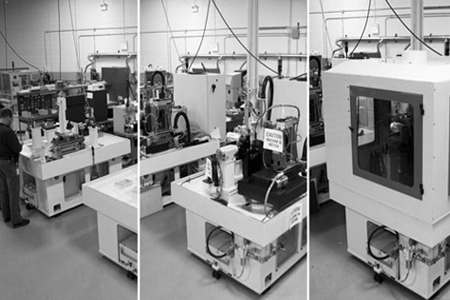

1. Clean and tidy workshop.

2.Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or according

to customer's requirement . It takes about 3-5 days to arrive your front

door, and proof of shippments are provided with a shipping or tracking

number. And we ship by occean shippment for larger quantity items,

it will be economic for customers.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang