Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

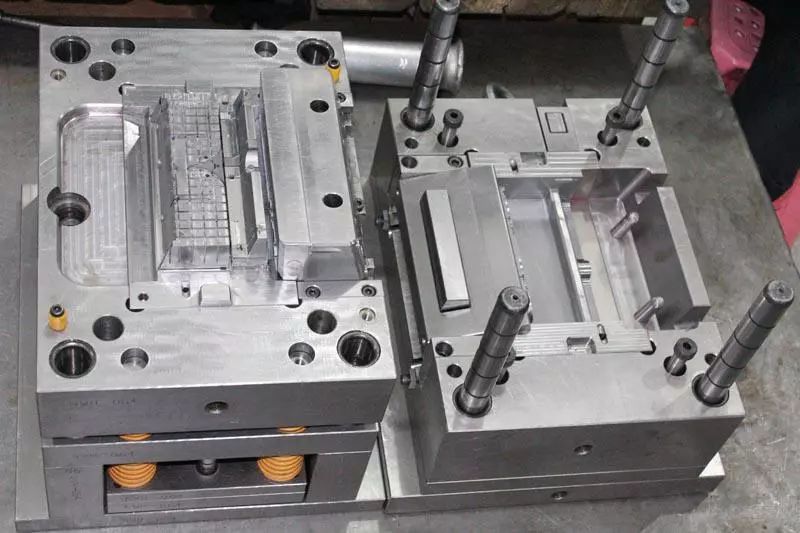

Medical Packaging Mold Parts | |

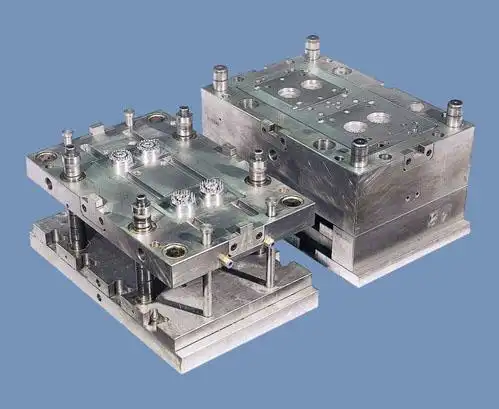

Product Name | Medical Device And Mold Accessories |

Brand Name | Fair Shine |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

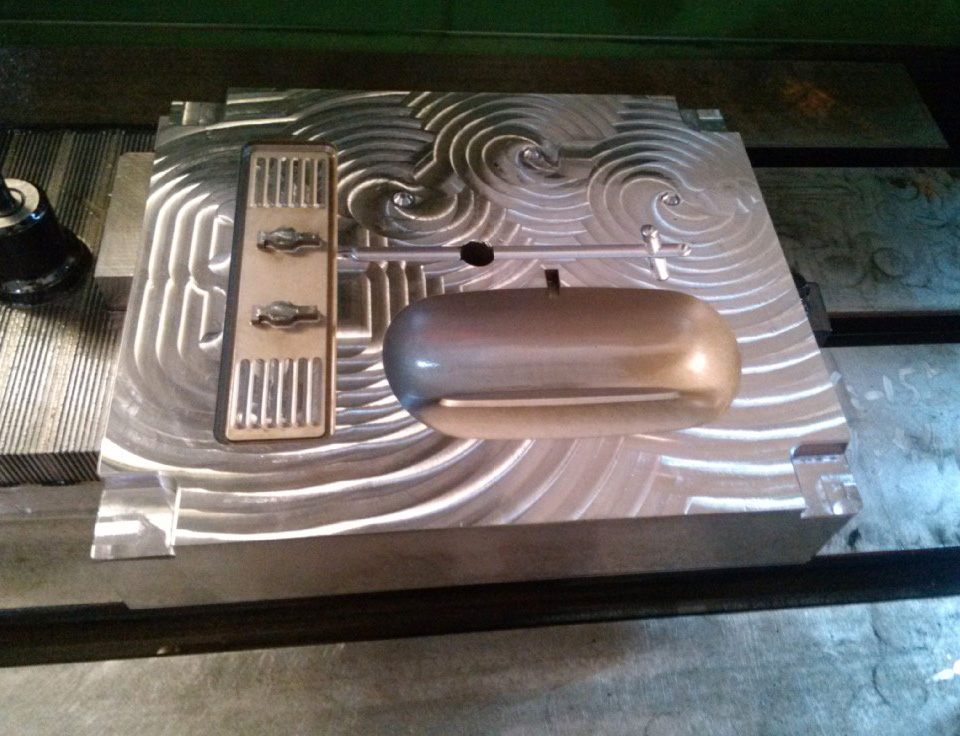

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Dongguan Huixiang Mold Technology Co., Ltd. specializes in manufacturing precision photoelectric shafts/threaded electrodes/pen model cores/cosmetic parts/precision inserts/cores/bushes and SKH51/SKD61 series barrel ejector mold accessories, etc.; .

products are widely used in Optoelectronics/digital electronics/medical packaging equipment/pen making/cosmetic packaging/electrical appliances/automobiles/mechanical motor axis manufacturing and other fields. The company's advantageous products include processing of non-standard mold parts, processing of brass + graphite wear-resistant blocks, processing of high-strength brass + graphite guide posts and bushings, processing of stainless steel guide posts and guide bushes, processing of various non-standard inserts, precision Plastic mold parts processing, metal stamping mold parts processing, die-casting mold parts processing, daily cosmetics mold parts processing, self-lubricating plates.

self-lubricating guide rails, self-lubricating guide posts and guide bushes, brass plus graphite wear-resistant block processing, high-strength yellow Copper plus graphite wear-resistant block processing, oil steel plus graphite wear-resistant block processing, cast iron plus graphite wear-resistant block processing, precision tooling and precision automated machinery parts and many other fields, we provide customers with comprehensive solutions for precision mold parts processing.

1. Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds;

2. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

3. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

4. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

5. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

6. Guide pins, positioning pins, stoppers Standard and non-standard customization of high columns, limit columns, etc.;

7. Non-standard customization of SKH51 thimbles, SKD61 thimbles, supporting pins, flat thimbles, shooting pins, cylinder pins, push tubes, imported material thimbles and cylinder cylinders;

8. Bushings, die inserts, lower molds, CNC Customized standard and non-standard precision stamping mold accessories such as concave molds, special-shaped bushings, contour sleeves, floating pins, cross pin floating pins, guide lifting pins, tungsten steel punches, etc.;

Immunoassay lid with 16 chambers: an innovative choice for optimizing immunoassays

In today's immunoassay field, the 16-chamber immunoassay cup cover, with its unique and excellent design and excellent performance, has become a key factor in promoting efficient and accurate testing.

Multi-chamber design: The 16-chamber layout is carefully planned and cleverly designed, with each chamber independent of each other and clearly separated. This carefully designed multi-chamber layout greatly improves the detection throughput, allowing a large number of samples to be processed at the same time. This advantage is particularly prominent in large-scale screening work and scenarios that require batch testing. It can significantly save valuable time and labor costs, and greatly improve the overall efficiency of testing work.

Disposable: The single-use feature provides unparalleled hygiene and safety to the testing process. Each test ensures the use of brand new, uncontaminated cup lids, eliminating the potential risk of cross-contamination from the source. This disposable design concept effectively guarantees the accuracy and reliability of each test result, providing a solid and credible data basis for medical diagnosis.

Sealing performance: It shows excellent sealing performance, which can effectively minimize the possible volatilization of samples during the detection process, while resolutely blocking the intrusion of external substances. Good sealing creates an ideal testing environment for the sample that is stable and free from external interference, ensuring that the properties of the sample during the testing process are stable and not affected by any external factors.

Leak-proof design: The carefully conceived and developed leak-proof structure can firmly ensure that the sample will not leak whether during normal and standardized operating procedures or when encountering extreme situations such as unexpected tilt and collision. This design not only perfectly protects the integrity of the sample and ensures the accuracy of the test data, but also successfully avoids contamination of the experimental environment caused by sample leakage, maintaining the cleanliness and safety of the laboratory.

Material Quality: High-quality medical-grade materials are strictly selected during the manufacturing process. These materials not only have excellent chemical stability and can maintain their own properties stable in the face of various complex chemical reagents and detection conditions, but also exhibit excellent biocompatibility and will not interact with the components in the sample. Any adverse reactions occur, thus effectively ensuring the authenticity and reliability of the test results.

Easy to operate: Its structural design fully takes into account the principles of ergonomics, the shape conforms to the grasping habits of human hands, and the installation process is simple and fast. Even in a busy and stressful laboratory working environment, operators can operate easily, quickly and accurately, greatly improving work efficiency and reducing errors that may occur due to inconvenient operation.

Logo and coding: The clear, eye-catching and easy-to-recognize logo and coding on the cup lid provides great convenience to experimenters. In all aspects of sample collection, processing and testing, recording and identification can be carried out conveniently and accurately, effectively reducing the probability of human errors, ensuring accurate correspondence between test results and samples, and facilitating subsequent data analysis and diagnostic decisions. Accurate evidence is provided.

Toilet cup lid-16-cavity precision mold: the fusion of innovation and excellence

1. Multi-hole design

The unique 16-cavity layout of this mold is one of its core advantages. By producing 16 toilet cup lids at one time, production efficiency is greatly improved and the market's large demand for such products is met. Each acupuncture point has been carefully calculated and optimized, and its spacing, size and shape have achieved a high degree of precision and uniformity. This multi-cavity design not only saves production time, but also reduces unit costs, bringing significant economic benefits to the enterprise.

2. Easy to carry

The toilet cup lid produced by this mold fully considers the actual use needs of users, and is designed to be lightweight and portable. Its moderate size and light weight make it easy for users to carry it with them when going out. Whether it is put into a backpack or a handbag, it will not cause additional burden. At the same time, the reasonable structural design makes the toilet cup cover easy to take and store, adding convenience to users' travel.

3. Health isolation

Hygiene and safety are of paramount importance in the design of toilet cup lids. The toilet cup lid produced by this mold can effectively achieve hygienic isolation and prevent external contaminants from entering the cup. Its tight-fitting design can block dust, bacteria and other harmful substances, ensuring the purity and safety of drinks. Whether in public places or outdoor environments, using such toilet cup lids allows people to enjoy drinks with confidence and protect their health.

4. Material safety

In terms of material selection, the toilet cup lid-16-cavity precision mold adheres to strict standards. The materials used comply with food safety and environmental protection requirements, are non-toxic, tasteless and harmless to human health. These high-quality materials not only ensure the safety of the toilet cup lid, but also have good corrosion resistance and durability, which can maintain its stable performance for a long time and are not easily deteriorated or damaged due to contact with drinks.

5. Sealing performance

Excellent sealing performance is a highlight of this mold. After precision processing and rigorous testing, the toilet cup lid can be tightly integrated with the cup to form a good sealing effect. Whether it is inverted, tilted or slightly squeezed, it can effectively prevent drinks from leaking. This feature eliminates the need for users to worry about spilling drinks during use, providing great convenience for daily use and portability.

6. Mold care and maintenance methods

01. Regular cleaning

After each use, residual plastic, oil, dust and other debris on the mold surface should be removed promptly to prevent their accumulation from affecting the performance and accuracy of the mold.

02. Lubrication treatment

Regularly add an appropriate amount of lubricating oil to the moving parts of the mold to reduce friction and wear and ensure smooth opening and closing of the mold.

03. Anti-rust protection

When the mold is not used for a long time, anti-rust oil should be applied and placed in a dry and ventilated environment to prevent rust.

04. Regular inspection

Check all parts of the mold regularly. If any wear, deformation or damage is found, repair or replace it in time.

05. Avoid collisions

During transportation and storage, care should be taken to avoid collisions and heavy blows to the mold to avoid loss of mold accuracy.

Our Services

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

Our adavanges

1. Clean and tidy workshop.

2.Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or according to customer's requirement . It takes about 3-5 days to arrive your front

door, and proof of shippments are provided with a shipping or tracking number. And we ship by occean shippment for larger quantity items,

it will be economic for customers.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang