Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2024-03-15 10:31:52

What is CNC Machining

CNC Machining is a technique for machining metals and other materials using a CNC machine, commonly known as "Computerised Numerical Control". This type of machining is programmed and controlled through the CNC machining language (usually G-code), which tells the CNC machine tool what Cartesian positional coordinates to use, and controls the tool feed rate and spindle speed, as well as the tool changer, coolant and other functions.

CNC Machining is an efficient, accurate and repeatable method of machining that is widely used in the manufacture of a wide range of mechanical parts.

What is the difference between CNC and Machining

In fact, CNC (Computerised Numerical Control) and Machining are closely related in many cases, but there are some differences in their definitions and uses.

Definition:

Machining: generally refers to machining or machine tool processing, which is a process of removing material by cutting, grinding, drilling, etc. to form a desired shape and size. This type of machining can be performed on manual, semi-automatic or fully automatic machine tools.

CNC (Computerised Numerical Control): i.e. Computer Numerical Control is a special type of machine tool control system that uses a computer program (usually G-code or M-code) to control the movement of the machine tool in order to automate machining tasks.CNC machine tools are capable of repeating the same machining operations with high precision and can handle complex geometries.

Applications:

Machining: covers many different types of machine tools and processes such as lathes, milling machines, grinding machines, drilling machines, etc. These machines can be operated manually or equipped with a numerical control (CNC) for automated machining.

CNC: Specifically refers to those machines that are equipped with a computerised numerical control (CNC) system.CNC machines automate machining tasks by reading pre-programmed commands that specify parameters such as tool travel paths, cutting speeds, feed rates, and so on.

Advantage:

Machining: On conventional machines without CNCs, operators need to manually control the machine to perform machining, which usually requires a high level of skill and experience. However, manual operation also provides greater flexibility and direct control over the machining process.

CNC: The main advantages of CNC machines are their high accuracy, efficiency and repeatability. Through programming, CNC machines can accurately replicate the same machining operations without fear of human error or skill differences. In addition, CNC machines can handle complex geometries that may be difficult to achieve on a manual machine.

Relationship:

CNC is a subset of Machining, i.e. CNC machining is a form of machining, but it uses computer numerical control technology for automation and precise control.

To summarise, Machining is a broader term that covers all types of machining techniques, whereas CNC is a specific area of Machining that uses computer numerical control technology to improve machining accuracy, efficiency and repeatability.

What is the difference between a CNC machine and a manual machine

Control: CNC machine tools use computer control technology, through pre-programmed instructions to control the movement of the machine tool and the machining process, to achieve automated machining. Manual machine tools, on the other hand, need to rely entirely on the operator's skills and experience, by manually adjusting and controlling various parts of the machine tool to complete the processing task.

Processing efficiency: Because CNC machine tools have a high degree of automation, machining speed characteristics, so it can significantly improve the processing efficiency, especially for mass production and high-precision machining process. In contrast, the manual machine tool processing efficiency is lower, and the quality of processing by the operator's skills and experience.

Machining accuracy: CNC machine tools have the advantages of high precision and good repeatability, can achieve high precision machining, especially for high precision, high requirements of the machining process. The machining accuracy of manual machine tools, on the other hand, is affected by the operator's skills and experience, and the accuracy is relatively low.

Scope of application: CNC machine tools are suitable for mass production and high-precision machining process, can achieve automated production, reduce production costs and improve product quality. Manual machine tools, on the other hand, are suitable for small batch production and processing of artwork, engraving and other products that require manual operation.

Flexibility and adaptability: CNC machine tools are flexible and adaptable, and can easily cope with different processing needs and process changes. Manual machine tools require operators to manually adjust and control the process according to the specific circumstances, so their flexibility and adaptability is relatively poor.

In addition, CNC machine tools are also characterised by expensive equipment, large investment and high requirements for workers' technical level. Although the operation of CNC machine tools requires certain skills and knowledge, once the relevant skills are mastered, efficient and high-precision processing can be achieved.

There are obvious differences between CNC machine tools and manual machine tools in terms of control, machining efficiency, machining accuracy, scope of application and flexibility and adaptability. The choice of which machine tool depends on the specific machining needs and process requirements.

What are the processes of CNC Machining

CNC Milling:this is one of the most common CNC Machining processes where material is removed by a rotating milling cutter to form the desired shape. CNC milling machines usually have multiple axes (e.g., 3, 4, or 5 axes) and are capable of handling a variety of complex geometries.

CNC Turning:CNC turning is the process of removing material by rotating a workpiece and using a cutting tool. CNC lathes are typically used to machine cylindrical parts such as shafts and bearings.

Sheet Metal Fabrication:Sheet metal processing is an important process for sheet metal processing, which mainly involves traditional methods such as cutting and discharging, punching and processing, and bending and pressing.

Plasma Cutting:Plasma Cutting is an efficient and precise metal cutting technology. It utilizes a plasma generated by a high-temperature ion gas to cut metal.

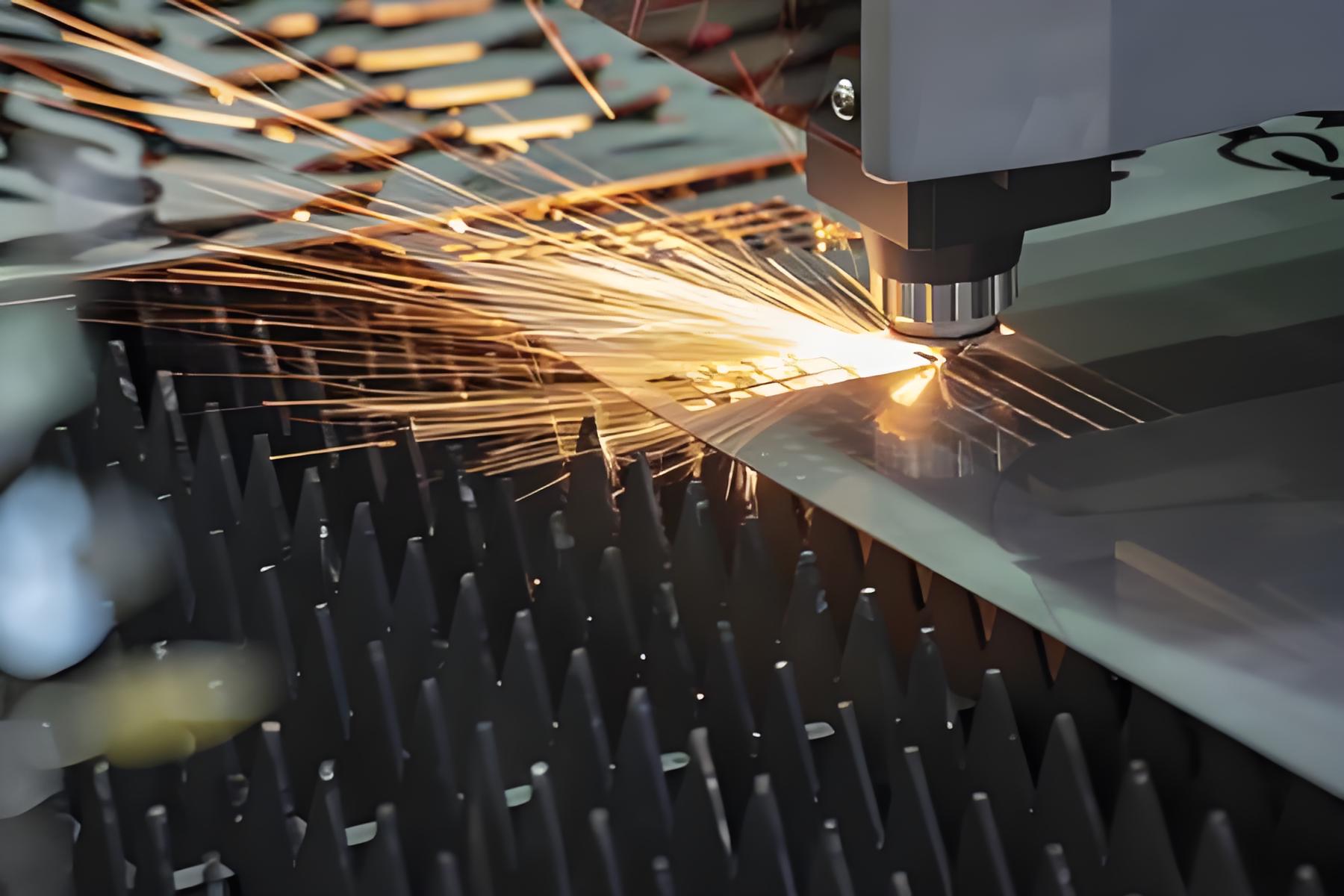

CNC Laser Cutting: This is a CNC machining process that uses a laser beam for cutting. It is suitable for a variety of materials including metals, plastics and composites.

CNC Wire Cutting:This process uses a fine wire (usually a metal wire) as a cutting tool to remove material by electric spark discharge. It is particularly suited to machining hard materials that are difficult to machine using traditional methods.

In addition, CNC Machining includes other specialised processes such as CNC drilling, tapping and reaming. The choice of these processes depends on the requirements of the workpiece in terms of material, shape, dimensional accuracy and surface finish.

CNC Machining is highly flexible and precise, capable of handling a wide range of complex machining requirements and is an integral part of modern manufacturing.

Fair Shine industrial, as a professional CNC Machining service provider, is committed to providing excellent machining services for each of your projects to make your products More outstanding.

Our equipment and technical team have the experience to deal with a wide range of complex shapes, providing you with the assurance of superior accuracy for your products.The equipment enables fast, accurate machining and dramatically shortens production lead times, helping you to respond quickly to market changes and take advantage of opportunities.

Whether it's metal, plastic or other materials, CNC Machining can handle it with ease. We have a variety of machining equipment and technology to meet your needs in different materials, different shapes, different precision machining.

We have an experienced and skilled team, which can provide you with a full range of services from design, processing to testing. We always pay attention to your needs, and constantly optimise the service process to ensure the successful completion of your project.

We always adhere to the principle of quality first, and carry out strict quality control on every processing link. With advanced testing equipment and professional testing team, we ensure that every product meets your requirements.

Choosing Fair Shine industrial is choosing high quality, high efficiency and full range of CNC Machining services.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang