Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2024-07-17 17:39:01

Molded plastic products are created through various molding processes, where raw plastic material is shaped into desired forms. Here are some common types of Plastic Molding Processes:

Types of Plastic Molding Processes

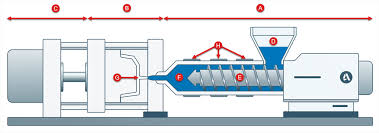

Process: Melting plastic pellets and injecting the molten plastic into a mold cavity.

Applications: Producing a wide variety of parts, from small components like gears and screws to large items like car body panels.

Materials: Thermoplastics such as ABS, polystyrene, polypropylene, and polyethylene.

Blow Molding:

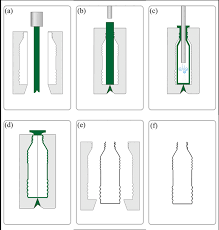

Process: Inflating a heated plastic tube until it fills a mold and forms the desired shape.

Applications: Making hollow plastic products like bottles, containers, and plastic drums.

Materials: Polyethylene, polyvinyl chloride (PVC), and polyethylene terephthalate (PET).

Rotational Molding:

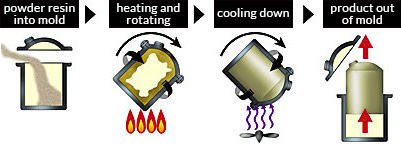

Process: Heating plastic in a mold that is rotated on multiple axes to ensure even coating and cooling.

Applications: Large, hollow products such as tanks, playground equipment, and kayaks.

Materials: Polyethylene, polypropylene, and nylon.

Thermoforming:

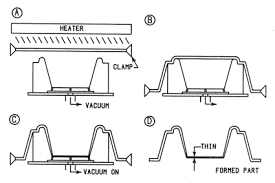

Process: Heating a plastic sheet until pliable, then forming it over a mold using vacuum, pressure, or mechanical means.

Applications: Packaging, disposable cups, trays, lids, and automotive panels.

Materials: Polystyrene, polyethylene, polycarbonate, and acrylic.

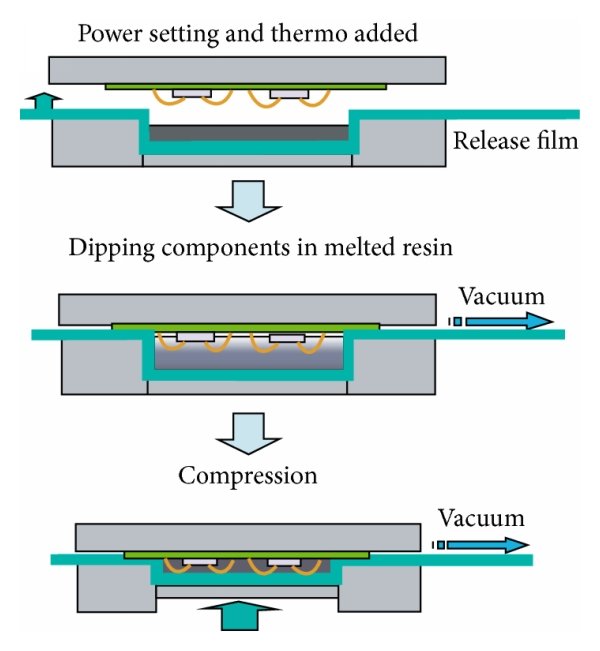

Compression Molding:

Process: Placing plastic material in a heated mold, then compressing it to form the desired shape.

Applications: Electrical components, automotive parts, and composite products.

Materials: Thermosetting plastics like phenolic, melamine, and epoxy.

Applications of Molded Plastic Products

Automotive Industry:Dashboard components, door panels, bumpers, and interior trims.

Automotive Industry:Dashboard components, door panels, bumpers, and interior trims.

Consumer Goods:Household items such as containers, toys, and electronic housings.

Medical Devices:Syringes, IV components, and diagnostic equipment housings.

Packaging:Bottles, caps, and various types of containers.

Electronics:Casings for phones, laptops, and other gadgets.

Benefits of Molded Plastic Products

Cost-Effective: Mass production reduces per-unit cost.

Versatile: Can create complex shapes and detailed features.

Lightweight: Easier to handle and transport compared to metal parts.

Durable: Resistant to corrosion and impact.

Customizable: Available in various colors and finishes.

Challenges and Considerations

Tooling Costs: High initial cost for mold creation.

Material Selection: Choosing the right plastic material for specific applications.

Quality Control: Ensuring consistency and precision in high-volume production.

Environmental Impact: Addressing issues related to plastic waste and recycling.

Molded plastic products play a crucial role in various industries due to their versatility, cost-effectiveness, and wide range of applications.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang