Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2024-08-01 15:29:13

Surface preparation inPrecision Machining is a critical step in ensuring that parts meet the required specifications and properties, which can improve the performance, durability and appearance of parts.

The following are some common surface treatment technologies and their applications in Precision Machining:

Polishing:

Function: Reduce the roughness of the surface of parts and improve the surface finish by mechanical, chemical or electrochemical methods.

Application: Commonly used for parts with high surface finish requirements such as optical components, medical devices and molds.

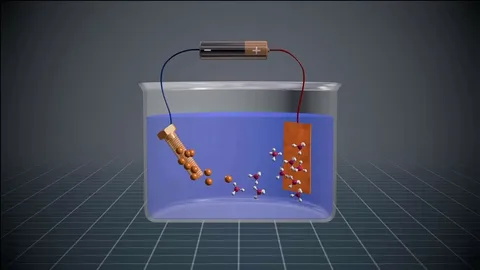

Electroplating:

Function: Deposit a layer of metal film on the surface of parts through electrolytic reaction to enhance corrosion resistance, conductivity and aesthetics.

Application: Widely used in electronic components, automotive parts and decorations.

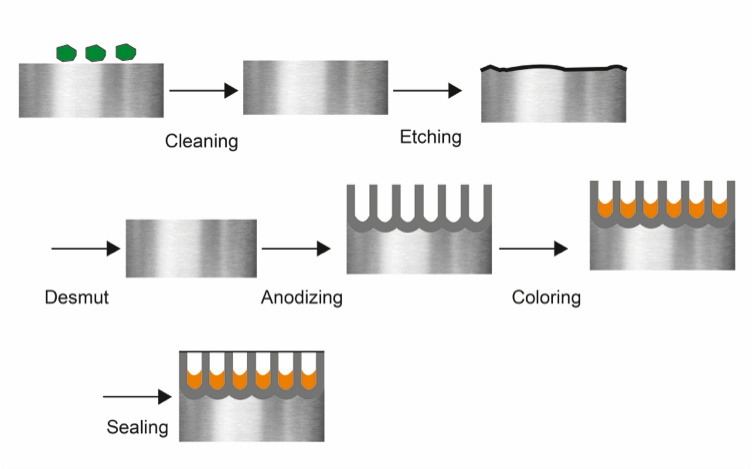

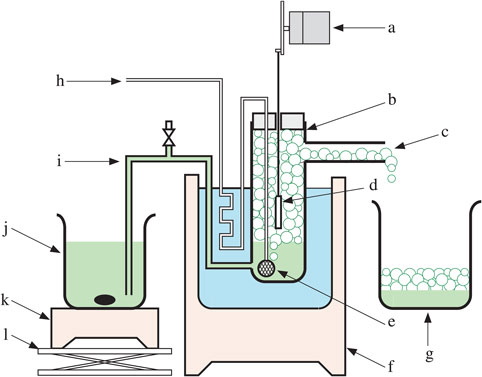

Anodizing:

Function: Generate an oxide film on the metal surface through electrolytic oxidation to increase the hardness and corrosion resistance of the surface and improve the appearance.

Application: Mainly used for surface treatment of aluminum and its alloys, such as aerospace, electronic product housing, etc.

Heat Treatment:

Function: Change the internal structure of the metal by heating and cooling to improve its mechanical properties, such as hardness, strength and toughness.

Application: Applicable to various metal parts, such as gears, bearings and tools.

Coating:

Function: Spray a protective or functional coating on the surface of a part by physical or chemical methods to improve wear resistance, corrosion resistance and lubricity.

Application: Including technologies such as powder spraying, liquid spraying and PVD (physical vapor deposition), widely used in industrial equipment, automotive parts and consumer electronics.

Electroless Plating:

Function: Deposit a metal film on the surface of a part by chemical reaction without external current.

Application: Suitable for parts with complex shapes and high precision requirements, such as electronic components and precision instruments.

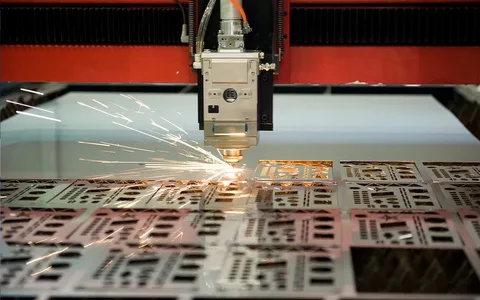

Etching:

Function: Remove the surface material of the part by chemical reaction or physical etching to achieve a specific shape and size.

Application: Used in semiconductor manufacturing, micro-electromechanical systems (MEMS) and printed circuit board (PCB) processing.

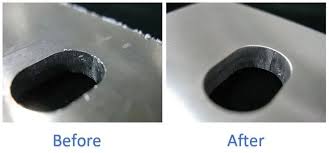

Deburring:

Function: Remove burrs and sharp edges generated during part processing by mechanical, thermal, chemical or electrolytic methods.

Application: Ensure smooth edges of parts to prevent problems during Assembly and use, widely used in automotive, aerospace and medical devices.

The choice of these surface treatment technologies depends on the material, purpose and required performance characteristics of the parts. In precision machining, the reasonable selection and application of surface treatment technology can significantly improve the quality and service life of parts.

Importance

Corrosion resistance: Many surface treatment methods (such as electroplating and anodizing) can significantly improve the corrosion resistance of parts and protect metal substrates from moisture, chemicals and oxidation in the environment.

Wear resistance: Methods such as hardening and spraying can enhance the wear resistance of parts, reduce wear and friction, and improve their service life and performance stability.

Appearance: Surface treatment (such as polishing and spraying) can improve the appearance of parts, increase gloss, meet aesthetic requirements, and also enhance the market appeal of products.

Functionality: Certain surface treatments (such as electrochemical polishing and chemical plating) not only improve the appearance, but also enhance the functionality of parts, such as conductivity, antibacterial properties or adhesion.

Dimensional accuracy: Appropriate surface treatment can reduce surface defects and improve the dimensional accuracy and Assembly quality of parts.

High temperature resistance: Certain treatments (such as thermal spraying and hardening) can improve the stability of materials in high temperature environments and are suitable for applications under high temperature working conditions.

Adhesion: Treatments such as spraying or chemical plating can improve the adhesion of coatings or adhesives, ensuring the success of subsequent processes (such as painting, gluing).

Reduce friction: Certain surface treatments (such as polishing) can reduce the coefficient of friction, thereby reducing friction losses and energy consumption and improving mechanical efficiency.

By selecting and applying appropriate surface treatment technologies, the performance, life and overall quality of parts can be optimized for specific working environments and usage requirements.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang