Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2024-05-30 17:12:09

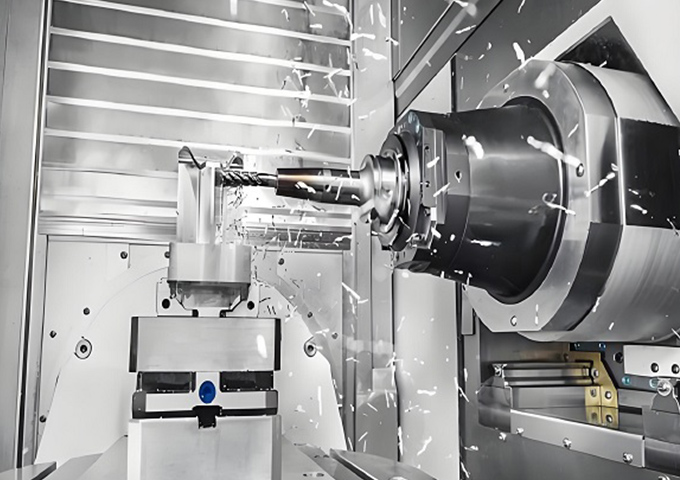

5 Axis CNC Machining is an advanced machining technology that enables the manufacture of complex shapes and high-precision workpieces. This machining technology uses a computer numerical control (CNC) system to control the movement of the cutting tool, enabling it to move on five different axes simultaneously. This multi-axis linkage capability gives 5-axis CNC Machining a unique advantage in the manufacture of complex parts.

How 5 Axis CNC Machining Works

In traditional 3-axis CNC machining, the cutting tool can only move along three axes: X, Y, and Z. In contrast, 5-axis CNC machining adds two rotational axes, commonly referred to as the A and B axes. This allows the cutting tool to access the workpiece from More angles, enabling more complex cutting paths and geometries.

Specifically, the two main configurations of 5-axis CNC machines include:

Double Rotary Axis Configuration: The machine table can rotate around the X and Y axes while the cutting tool moves along the X, Y, and Z axes.

Single Rotary Axis Configuration: The table moves along one rotational axis while the cutting tool rotates around another axis.

5-axis CNC machining can be divided into the following types according to its process characteristics:

Simultaneous 5-Axis Machining: The cutting tool and the workpiece move simultaneously on five axes to achieve the machining of complex surfaces and shapes. This process is suitable for the manufacture of high-precision, complex parts, such as aerospace parts.

3+2 Axis Machining: The cutting tool moves on three linear axes while the workpiece is fixed at specific angles on two rotational axes for machining. This method is usually used for workpieces with complex geometries but relatively simple machining paths.

Dynamic Tilted Head Machining: By changing the tilt angle of the cutting head to adapt to different machining positions and directions, the flexibility and accuracy of machining are enhanced.

Applications of 5 Axis CNC Machining

Due to its high flexibility and accuracy, 5-axis CNC machining is widely used in multiple industries, including but not limited to:

Aerospace: Manufacturing complex aircraft parts such as turbine blades, engine components and structural parts.

Automotive Industry: Used to produce high-performance engine components, transmission components and customized automotive parts.

Medical Devices: Manufacturing complex medical devices and implants such as artificial joints and dental appliances.

Energy: Including wind turbine blades and complex pipe connections.

Mold Making: Producing high-precision molds for Injection Molding and die casting.

5-axis CNC machining machines can be used in manufacturing sites of all sizes, from small factories to large industrial production lines. Common 5-axis CNC machine types include:

Gantry-Type Machining Center: Suitable for machining large workpieces, commonly used in aerospace and shipbuilding.

Vertical Machining Center (VMC): Suitable for machining small and medium-sized workpieces, widely used in various manufacturing industries.

Horizontal Machining Center (HMC): Due to its stability and efficiency, it is suitable for mass production of high-precision parts.

Multi-Tasking Machining Center: Capable of performing multiple processes such as turning, milling and drilling, suitable for integrated machining of complex parts.

Advantages of Fair Shine Industrial

As a professional CNC machining service provider, Fair Shine Industrial has the following advantages:

Advanced equipment: The company is equipped with the latest 5-axis CNC machining equipment, which can meet the machining needs of various complex parts.

Professional technical team: The experienced technical team can provide one-stop service from design to manufacturing to ensure product quality and machining efficiency.

Strict quality control: The internationally advanced quality control system is adopted to ensure that every part meets the customer's technical requirements and standards.

Flexible production capacity: Whether it is small batch custom production or large-scale mass production, Fair Shine Industrial is able to respond flexibly to meet the needs of different customers.

As an advanced manufacturing technology, 5 Axis CNC Machining is widely used in multiple industries with its high precision, high flexibility and versatility. By adopting advanced equipment and technology, Fair Shine Industrial is able to provide high-quality 5-axis CNC machining services to meet the diverse needs of customers in different application fields. Whether it is aerospace, automotive industry or medical equipment, 5-axis CNC machining has demonstrated irreplaceable advantages and provided strong support for the development of modern manufacturing.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang