Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2024-06-07 11:33:03

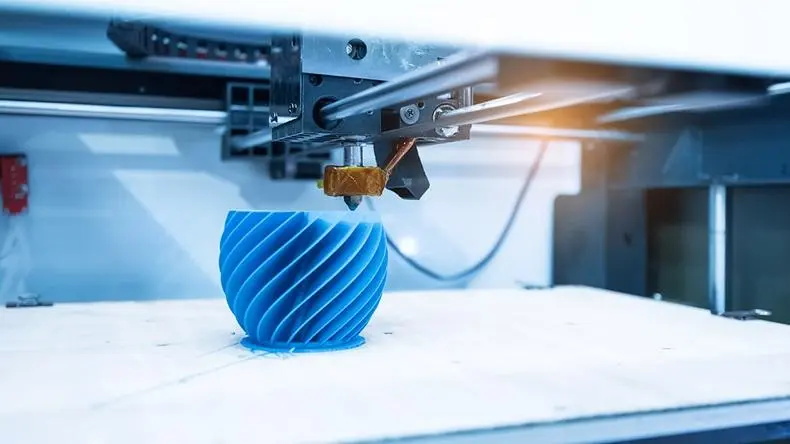

What is 3D Printing?

3D Printing, also known as Additive Manufacturing, is a technology that creates three-dimensional objects by adding material layer by layer. Unlike traditional subtractive manufacturing methods (e.g., turning, milling), 3D printing creates objects from scratch, usually starting with a digital design file.

Basic Principles of 3D Printing

The basic process of 3D printing can be divided into the following steps:

Design model: first, a 3D model is needed. Computer Aided Design (CAD) software is usually used to create this model. It is also possible to convert a physical object into a digital model using 3D scanning technology.

File preparation: The designed 3D model files are usually saved in STL or OBJ format. These files need to be processed, layered and a print path generated, a step called slicing. The slicing software will divide the model into many thin layers and generate the print path for each layer.

Print Setup: Upload the sliced file to the 3D printer and make print settings, including material selection, print speed, layer thickness and other parameters.

Printing process: The 3D printer prints layer by layer according to the pre-set path until the whole model is completed. The printing material will vary according to the printing technology, such as plastic, metal, ceramic, resin and so on.

Post-processing: After printing, some post-processing steps, such as removing support structures, surface sanding, painting, etc., are usually required to obtain the desired appearance and functionality.

Types of 3D Printing Technology

There are various types of 3D printing technologies, mainly including:

Fused Deposition Modelling (FDM, Fused Deposition Modeling: uses thermoplastic materials (e.g. PLA, ABS) that are melted and deposited layer by layer through a heated nozzle.FDM is one of the most common and economical 3D printing technologies.

Stereolithography (SLA, Stereolithography: Using photosensitive resin, cured layer by layer by UV laser. SLA is able to achieve high precision and high detail.

Selective Laser Sintering (SLS, Selective Laser Sintering): uses a laser to sinter powdered materials (e.g., nylon, metal powder) layer by layer to form a robust part. sLS is suitable for functional prototyping and low-volume production.

DLP (Digital Light Processing): Similar to SLA, but uses a digital projector light source for layer-by-layer curing; DLP is typically faster than SLA.

Electron Beam Melting (EBM, Electron Beam Melting: Uses an electron beam to melt metal powder to create metal parts layer-by-layer. EBM is used in the aerospace and medical fields to manufacture high-performance metal parts.

Material Jetting: Similar to 2D inkjet printers, liquid photosensitive materials are sprayed layer by layer through a nozzle and cured by UV light. It enables multi-material and multi-colour printing.

Application areas of printing

3D printing technology is used in many fields due to its flexibility and versatility:

Manufacturing: for Rapid Prototyping, tooling, custom part production, and small batch production.

Medical: customised medical devices, prosthetics, implants and anatomical models. Capable of being personalised to the patient.

Aerospace: manufacturing lightweight, high-strength parts to reduce the weight and fuel consumption of aircraft.

Architecture: create complex architectural models and even directly print building components.

Education: as a teaching tool to help students understand complex concepts and design principles.

Art and design: for creating unique artwork, jewellery and fashion designs.

Advantages and Challenges of 3D Printing

Advantages

Design Freedom: enables the realisation of complex structures that are difficult to process with traditional manufacturing methods.

Rapid prototyping: Dramatically reduces the time from design to physical model, facilitating rapid iteration and innovation.

Personalisation: suitable for producing customised products such as medical implants and personalised gifts.

Material savings: Reduce waste by using only the materials you need.

Challenges

Material limitations: Although the range of available materials is growing, it is still limited, especially for certain high-performance materials.

High cost: the high cost of high-end 3D printers and materials is still not economically advantageous for mass production.

Accuracy and strength: the accuracy and strength of certain 3D printing technologies may not be sufficient for demanding applications.

Knowledge and skill requirements: Operating and maintaining 3D printers, as well as designing and slicing, require specialised knowledge and skills.

Future Developments

3D printing technology is progressing and future breakthroughs are expected in the following areas:

Material innovation: development of More high performance materials, including biomaterials and smart materials.

Printing speed: increase printing speed and reduce production time.

Mass production: Achieve more economical mass production and reduce costs.

Multi-functional printing: Combine multiple printing technologies to achieve multi-material and multi-functional parts manufacturing.

Application expansion: find new applications in more fields, including food printing and bioprinting.

3D printing, as a revolutionary manufacturing technology, is changing production methods and design concepts in all industries. As the technology continues to evolve and innovate, 3D printing will open up even more possibilities for the future.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang