Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2025-04-14 16:52:34

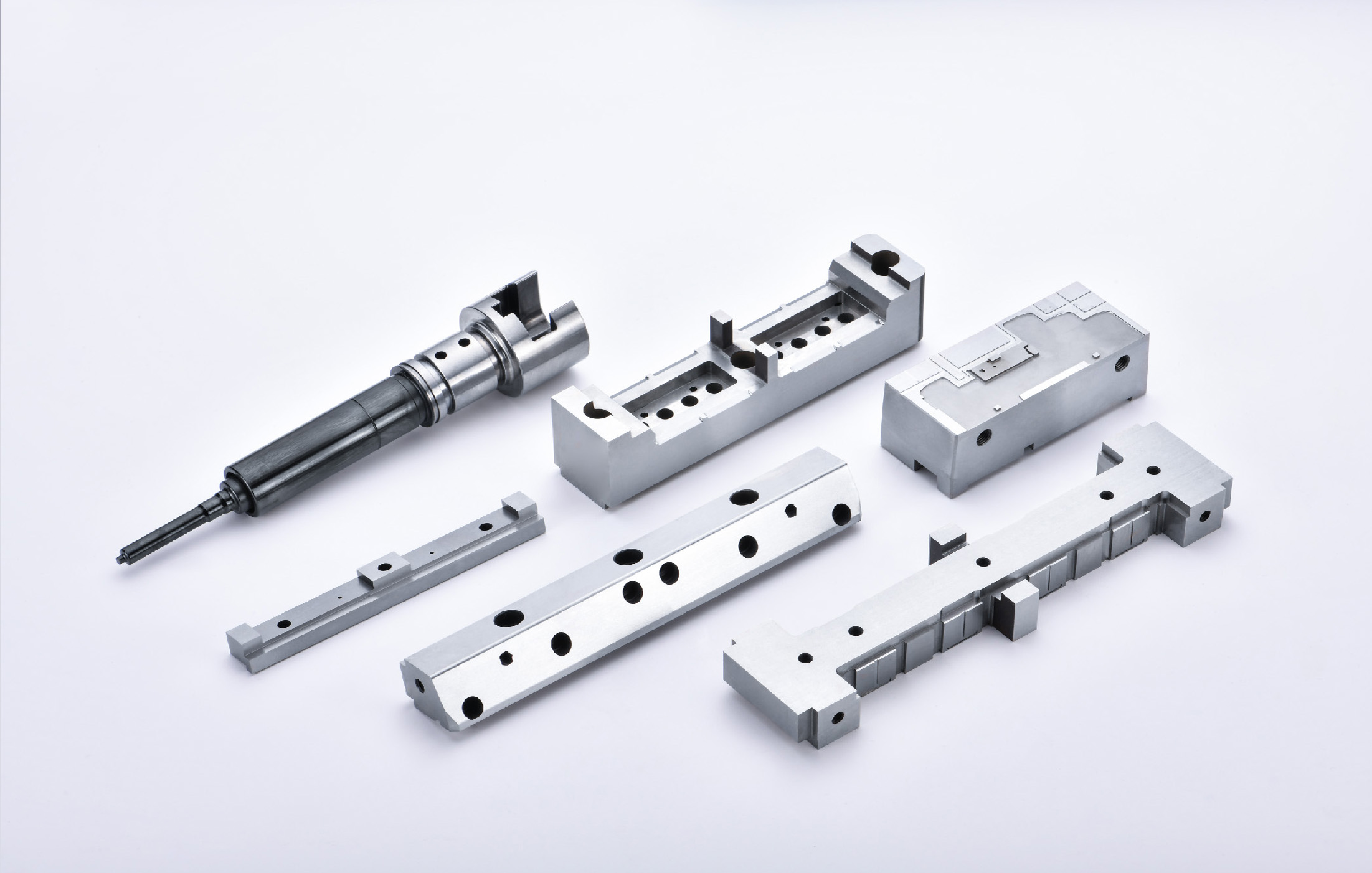

Stamping Mold Inserts are replaceable parts used in metal stamping dies. They are installed at key positions of stamping dies to complete process operations such as blanking, bending, and strEtching. They are usually subjected to high-frequency impact and pressure and are key components in the mold system that determine the forming accuracy and service life.

Application:

Stamping Mold Inserts are mainly used in the stamping manufacturing process of various metal parts. They are often used in molds for products such as automotive parts, electronic components, hardware tools, home appliance housings, and communication equipment. By replacing mold inserts of different shapes, sizes, or structures, the mold function can be quickly adjusted to achieve customized production or extend the overall life of the mold.

In the structure of stamping dies, they are often used in locations that require high-precision forming, frequent replacement, or high-stress strength, such as trimming, perforation, and bending. They can also be used for mold repair or local modification to reduce maintenance costs and improve production efficiency.

Material:

Stamping Mold Inserts are usually made of high-strength, wear-resistant alloy steel or tool steel. Common materials include SKD11, DC53, Cr12MoV, ASP23, powder high-speed steel, cemented carbide (tungsten steel), M2, H13, etc. These materials are tempered, vacuum heat treated, surface nitrided or PVD coated to improve hardness, impact resistance and corrosion resistance. Some high-end custom inserts are also made of a variety of materials to meet special high temperature resistance, high pressure or micron-level precision requirements.

Features:

High precision: Manufactured using advanced processes such as CNC Machining and EDM, with high dimensional accuracy and extremely small clearance

Wear-resistant and impact-resistant: High-hardness steel is selected and heat-treated, with good wear resistance and high-frequency impact bearing capacity

Replaceable design: The insert structure is easy to install and replace, saving maintenance time and extending the life of the entire mold

Diversified customization: Inserts of different shapes, structures and materials can be customized according to part drawings and processing requirements

Strong applicability: Suitable for a variety of stamping types of molds, including single-punch molds, compound molds, continuous molds, etc.

Heat treatment reinforcement: Usually high-temperature tempering, vacuum quenching or PVD coating to enhance durability

Combined structure: Convenient for partition design and partial replacement, improving the modularity of the mold

Advantages:

Extend the service life of the mold: By replacing the inserts in the worn parts, the overall mold can be avoided from being scrapped and maintenance costs can be reduced

Improve product quality: High-precision inserts ensure that the edges of the stamped parts are flat and the error is small, improving the consistency of the finished product

Shorten maintenance time: The design that can be quickly disassembled and assembled greatly shortens the mold downtime and improves production efficiency

Achieve customized processing: Design insert structures according to different needs of parts to adapt to diversified production tasks

Applicable to high-load scenarios: High-strength materials can withstand frequent impacts and long-term continuous stamping operations

Reduce overall costs: Regular replacement of inserts as wear parts can effectively reduce the cost of repeated purchases of the entire mold

Easy to upgrade molds: By replacing or adjusting the insert design, mold modification and function expansion can be quickly completed

FAQ:

What types of molds are Stamping Mold Inserts suitable for?

Suitable for all types of metal stamping molds, including continuous molds, compound molds, stretching molds, bending molds, etc., especially suitable for mold structures that frequently replace parts or require high-precision processing.

Can the inserts be replaced separately after wear?

Yes. Stamping Mold Inserts are designed as replaceable structures. You only need to replace local inserts without replacing the entire mold. The maintenance efficiency is high and the cost is lower.

What materials are available?

Common materials include SKD11, DC53, Cr12MoV, M2, cemented carbide, etc. Choose the appropriate steel grade and heat treatment process according to the material of the stamping parts and the frequency of use to achieve the best durability and cost-effectiveness.

What is the machining accuracy?

Usually the machining accuracy can be controlled within ±0.005mm, and some high-precision inserts can reach ±0.002mm, which is suitable for electronic components or medical molds with extremely high precision requirements.

Do inserts need surface treatment?

Most inserts require surface hardening treatment, such as nitriding, PVD coating or high-frequency quenching, to improve wear resistance and corrosion resistance, enhance service life and product stability.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang