Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2025-04-23 16:25:58

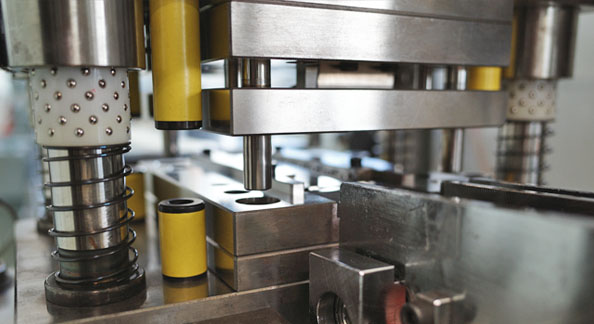

Stamping mold inserts are precision mold components used to manufacture various metal parts. They are usually made of steel, aluminum, or other durable materials and are inserted into the mold during the stamping process to help form metal parts. The role of stamping mold inserts is to ensure the accuracy and durability of the mold in long-term use. These inserts can produce high-quality, complex-shaped parts according to specific design requirements. They are widely used in industries such as automobiles, electronics, home appliances, and machinery.

Material:

Steel: Steel is the most commonly used material for manufacturing stamping mold inserts, with excellent strength and wear resistance. Common steels include carbon steel, stainless steel, alloy steel, etc. Different types of steel materials can be selected according to specific stamping requirements.

Aluminum alloy: Aluminum alloy is widely used in molds for light stamping parts due to its lightness and excellent corrosion resistance. Although aluminum alloy is not as hard as steel, it is lightweight and easy to process, making it suitable for less demanding applications.

Copper and copper alloys: Copper and its alloys are often used for parts that require good electrical and thermal conductivity, especially in the electronics industry. Their corrosion resistance also makes these materials suitable for use as stamping die inserts.

Plastics: For certain lightweight or corrosive applications, plastic mold inserts are also used, especially when producing electronic products and home appliances. Common plastic materials include polycarbonate (PC), polypropylene (PP), polyamide (PA), etc.

Applications:

Stamping mold inserts are mainly used in the production of metal parts, especially in areas that require high precision and durability. Specific uses include:

Automotive industry: In the automotive industry, stamping die inserts are used to produce body, chassis, engine parts, etc. They help reduce vehicle weight, improve production efficiency, and ensure the structural stability of the product by providing a precise molding process.

Electronics industry: In the production of electronic products, stamping die inserts are often used to manufacture parts such as housings, connectors, and circuit board brackets. Through precise processing, the safety and functionality of electronic products are guaranteed.

Home appliance industry: Metal parts of home appliance products are often manufactured by stamping die inserts, such as switches, buttons, and housings. These inserts ensure the long-term durability of home appliance parts.

Mechanical industry: The use of stamping die inserts in the mechanical industry is mainly concentrated in the production of various mechanical equipment parts, providing high precision and durability to support the efficient operation of mechanical equipment.

Construction industry: In the construction industry, stamping die inserts are used to produce steel structures, door and window frames, decorative parts, etc., providing stability and aesthetics.

Features:

High precision: The design and manufacturing precision of stamping die inserts are very high. Through precise processing technology, the dimensions of the mold and the molded parts can be guaranteed to be accurate and meet strict tolerance requirements.

Strong durability: Stamping die inserts are made of highly wear-resistant materials, which can maintain stable performance and extend service life during long-term stamping operations.

Complex shape processing capability: Stamping die inserts can process complex parts shapes, including various small and precise structures, which makes them occupy an important position in diverse industry applications.

Strong material adaptability: Stamping die inserts can be processed using a variety of materials to meet product specifications with different requirements. Whether it is metal, plastic, or other composite materials, they can be accurately processed through appropriate insert design.

High production efficiency: The production process using stamping die inserts can efficiently produce a large number of similar products, greatly improving production efficiency and reducing the cost of single-piece production.

Advantages:

High cost performance: The manufacturing cost of stamping die inserts is relatively low, especially in mass production. Due to its efficient production method, the unit cost will be significantly reduced, thereby improving the cost performance of overall production.

High strength and durability: Stamping die inserts made of high-strength materials such as steel can withstand large mechanical pressure, have excellent wear resistance and impact resistance, and are suitable for use in harsh working environments.

Flexible design and customization: Stamping die inserts can be designed into various complex shapes according to different application requirements. Designers can customize the mold shape, size and material according to customer needs to achieve personalized production needs.

Quick response to production cycle: Since stamping die inserts can be produced efficiently, the production cycle of the mold is short, which can quickly respond to market demand and adapt to the fast-paced manufacturing industry.

Environmental protection and energy saving: Modern stamping technology can effectively reduce material waste, especially when using recyclable metal materials, and the recycling of resources can be achieved during the production process, which meets environmental protection standards.

Why choose Stamping Mold Inserts?

Improve production efficiency: Stamping mold inserts can mass-produce high-precision parts, thereby greatly improving production efficiency. This has irreplaceable advantages for industries that require mass production, especially the automotive and electronics industries.

Ensure product quality: The high-precision manufacturing capabilities provided by stamping mold inserts ensure the consistency and stability of each component, avoid quality fluctuations caused by mold problems during the production process, and improve the quality of the final product.

Cost savings: Compared with traditional processing methods, stamping mold inserts can achieve higher automation production, reduce manual operation errors and production time, thereby reducing production costs.

Strong adaptability: Whether it is the automotive, electronics or home appliance industry, stamping mold inserts can be designed and applied according to different production needs to meet the requirements of different materials, shapes and processes.

Continuous technological innovation: With the continuous advancement of manufacturing processes, the design and manufacturing of stamping mold inserts are also constantly innovating, especially the use of More advanced materials and processing technologies, which have continuously improved the durability, efficiency and precision of molds.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang