Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

2024-06-29 15:12:17

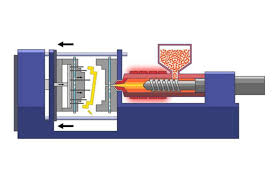

Injection Molding is a production process used to manufacture plastic parts. It involves injecting molten plastic material into a mold, cooling and solidifying to form a workpiece of the desired shape. This method is widely used to manufacture a variety of products, from small precision parts to large complex components.

The process of Injection Molding

Material preparation: Plastic pellets (resin) are fed into the hopper of the Injection Molding machine and heated to a molten state by a heating device.

Injection: The molten plastic is injected into the closed mold cavity through the injection device. High pressure makes the plastic fill all the voids in the mold.

Cooling: The plastic cools and solidifies in the mold. Cooling channels in the mold help speed up the cooling process.

Demolding: The mold opens and the molded plastic part is pushed out or taken out.

Post-processing: Remove any excess material or burrs, and some additional processing may be required, such as painting, Assembly or inspection.

Advantages of injection molding

Efficient production: Suitable for mass production and fast production speed.

Complex shapes: Able to produce complex and precise parts to meet various design requirements.

Material diversity: A variety of plastic materials can be used, including thermoplastics, thermosets and elastomers.

High degree of automation: Modern injection molding machines are often equipped with automation systems to improve production efficiency and consistency.

Low waste: High material utilization and low waste help reduce costs and reduce environmental impact.

Application areas

Injection molding is widely used in multiple industries, including:

Injection molding is widely used in multiple industries, including:

Automobile manufacturing: manufacturing various automotive parts such as dashboards, door panels, bumpers, etc.

Electronic products: producing mobile phone housings, computer accessories, connectors, etc.

Household appliances: manufacturing home appliance housings, built-in parts, etc.

Medical devices: producing medical equipment parts, disposable medical supplies, etc.

Packaging: producing various plastic packaging containers and bottle caps.

Consumer goods: manufacturing toys, household items, tool handles, etc.

Precautions for injection molding

Mold design: Mold design directly affects product quality and production efficiency, and requires precise design and manufacturing.

Material selection: Select appropriate plastic materials according to product requirements, considering their mechanical properties, heat resistance, chemical resistance, etc.

Process parameter control: Accurately control process parameters such as injection temperature, pressure, cooling time, etc. to ensure product consistency and quality.

Equipment maintenance: Regularly maintain injection molding machines and molds to ensure normal operation of equipment and product quality.

Injection molding is an efficient and flexible manufacturing process that is suitable for the production of various plastic parts and occupies an important position in modern manufacturing.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang