Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

SKD61-Precision Mould Parts | |

Product Name | SKD61-Precision Mould Parts |

Brand Name | Fair Shineg |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Surface Treatment | TiCN, TiN, TiALM, Ticrn, Nitriding , Black Oxygened, Black Coating Etc Available |

Closest | ±0.005mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC50~64) |

Supply Ability | 2000pcs/week |

Shaping Mode | Grinding, wire cutting, EDM, CNC machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Dongguan Huixiang Mold Technology Co., Ltd. is a comprehensive enterprise integrating production and sales, with a sales network covering the whole country. Huixiang Mold Company focuses on the manufacturing of non-standard spare parts such as precision plastic mold cores, insert pins, inserts, and die-cast model cores. The company has an elite technical team with many years of experience in the production of mold parts. It can fully integrate foreign advanced technology with the Chinese market and provide customers with professional precision mold processing technology solutions and high-quality precision parts products.

THuixiang Mold Company's products are widely used in precision plastic molds, metal stamping molds, die-casting molds, precision automation machinery parts and many other fields. Professionally produced mold accessories include: ejector pins, support pins, flat ejector pins, cylinders, guide posts, guide bushes, insert pins, inserts, wear-resistant blocks, limit clamps, precise positioning, auxiliary devices, clamping buckles, and die-casting models. Customized cores, punches, dies, springs, non-standard parts, etc. The raw materials of the products are purchased from Japan, Germany, and Sweden according to customer needs, and are accompanied by material certificates or processed with supplied materials. The performance is stable. The heat treatment is provided with supporting services from professional manufacturers, and is equipped with advanced production equipment and experienced professional and technical personnel. The accuracy, performance and service life of the product are superior, and the service is more convenient!

Huixiang Mold Company uses ERP information management system and paperless office system, combined with network management system, so that customers can place orders directly and check product status through the website. Realize resource sharing with customers, making information and logistics transmission faster..

We will always adhere to the principle of honesty and customer first. Provide customers with consistently high-standard products with advanced production technology, efficient production methods and reasonable prices. We implement an advanced quality control model, implement rigorous quality inspection, strive to create an excellent mold accessories brand, and wholeheartedly provide new and old customers with better products, faster delivery, and better services.

1. Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds;

2. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

3. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

4. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

5. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

6. Bushings, die inserts, lower molds, CNC Customized standard and non-standard precision stamping mold accessories such as concave molds, special-shaped bushings, contour sleeves, floating pins, cross pin floating pins, guide lifting pins, tungsten steel punches, etc.;

7. Guide pins, positioning pins, stoppers Standard and non-standard customization of high columns, limit columns, etc.;

8 . Guide post guide bushing, GP auxiliary guide post, GP auxiliary guide bushing, SRP ball guide post guide bush, SGP sliding guide post guide bush, discharge plate guide post guide bush, TRP detachable guide post guide bush, independent guide post , non-standard guide posts and bushings and other cold stamping mold accessories; .

Special precision manufacturing mold parts - bushings

On the grand stage of modern industry, mold parts are like "screws" of precision machinery. Although they may seem small, they play a decisive role in overall performance. Among them, the bushing is one of the key parts, with its unique

Performance occupies an indispensable position in industrial production.

1.Wear resistance

Bushings often face frequent friction and wear during work. To ensure its stable operation over a long period of time, excellent wear resistance is a key feature. High-quality bushings are usually made of special wear-resistant materials, such as heat-treated alloy steel or ceramic materials with high hardness. The tight microstructure of these materials effectively resists wear and tear caused by friction. For example, in the transmission systems of some heavy machinery, bushings need to work continuously under high load and high speed conditions. Their excellent wear resistance makes the relative movement between components smooth and unobstructed, greatly extending the service life of the equipment.

2.Corrosion resistance

In many industrial environments, corrosion is a problem that cannot be ignored. Bushings can be exposed to a variety of chemicals, moisture, and harsh operating media. Therefore, good corrosion resistance is crucial. By using corrosion-resistant alloy materials such as stainless steel or special anti-corrosion treatments on the surface, the bushing can maintain its structural and performance integrity in corrosive environments. In fields such as chemical industry and marine engineering, the corrosion resistance of bushings enables them to operate stably under harsh working conditions and avoid failures and malfunctions caused by corrosion.

3. High temperature stability

Some special industrial applications expose bushings to high temperatures. At this time, high temperature stability becomes one of its essential properties. High temperatures can cause softening, deformation and even performance degradation of materials. Advanced bushing designs use high-temperature-resistant materials, such as high-temperature alloys or ceramic composites, that can maintain their mechanical strength and dimensional stability under high-temperature conditions. For example, in engine components in the aerospace field, bushings need to work normally under the impact of high-temperature gas, and their excellent high-temperature stability ensures the safe and reliable operation of the engine.

4. Precision and Tolerance

Accuracy and tolerance control are core requirements for bushing manufacturing. The dimensional accuracy of the bushing directly affects the installation accuracy and movement accuracy of its mating components. Micron-level tolerance control ensures a tight fit between the bushing and shafts, holes and other components, reducing looseness and gaps, thus improving the operating accuracy and stability of the mechanical system. In fields such as precision machine tools and semiconductor manufacturing equipment, the accuracy of bushings is extremely high. Any slight deviation may affect the quality of the product and the performance of the equipment.

5. Ease of processing

Despite the stringent performance requirements of bushings, good processability is also an important factor to consider in their design and manufacture. Ease of processing allows bushings to be produced in series in an efficient and economical manner. By optimizing material selection and manufacturing processes, such as using advanced cutting, grinding and heat treatment processes, it can not only meet the high performance requirements of the bushing, but also improve production efficiency and reduce production costs. This is of great economic significance for large-scale industrial production.

6. Good lubricity

In order to reduce friction and wear, bushings usually need to have good lubrication properties. By designing reasonable lubrication grooves on the surface of the bushing or using oil-containing self-lubricating materials, the lubrication state can be effectively maintained during the working process. Good lubricity not only reduces energy loss, but also reduces heat and noise, improving the operating efficiency and comfort of the entire mechanical system. In fields such as automotive engines and industrial transmission systems, bushings with good lubrication properties effectively reduce the friction coefficient and improve fuel economy and system reliability.

To sum up, bushings, as special precision-made mold parts, are widely used in modern industrial production due to their excellent wear resistance, corrosion resistance, high temperature stability, precision and tolerance control, easy processability and good lubricity. plays a vital role. Its performance directly affects the operating efficiency, accuracy and reliability of the entire mechanical system, and it is an indispensable key component in the industrial field. With the continuous advancement and innovation of industrial technology, the performance of bushings will continue to improve, providing stronger support for promoting industrial development and technological progress.

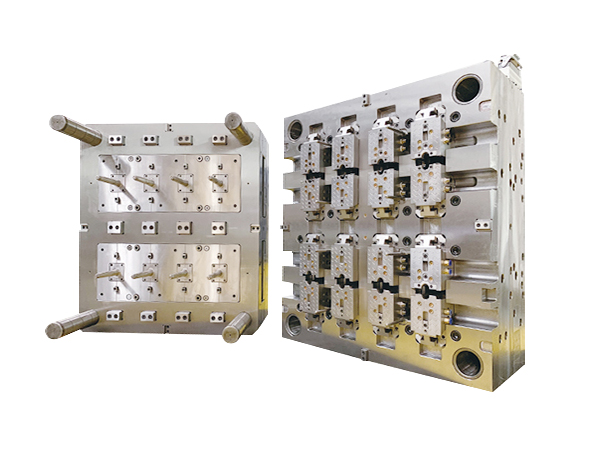

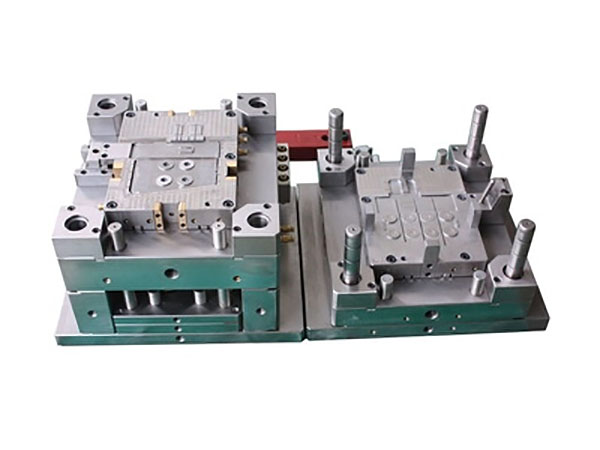

12-Cavity Hot Runner Precision Filter Mold: Outstanding Innovation in Manufacturing

In the vast field of modern manufacturing, the 12-cavity hot runner precision filter mold is like a shining star. With its unique design and excellent performance, it has made great contributions to the production of high-quality precision filters.

Multi-cavity design: double improvement in efficiency and output

The careful layout of the 12 cavities is a distinguishing feature of this mold. Rather than simply increasing the number of chambers, it is based on in-depth engineering analysis and optimization. The size, shape and position of each cavity have been precisely calculated to ensure that during the injection molding process, the plastic melt can be filled evenly and quickly to avoid local shortage or overfilling. The most direct benefit brought by this multi-cavity design is the substantial improvement in production efficiency. A 12-cavity mold can produce more product at the same time than a traditional single-cavity or fewer-cavity mold. For example, when responding to urgent and large orders, it can quickly meet market demand, winning valuable time and market share for the company. At the same time, the multi-cavity design also helps reduce the production cost per unit product. Through the scale effect, the waste of raw materials and energy consumption in the production process are reduced, giving enterprises a more obvious price advantage in market competition.

Hot runner system: a powerful tool for precise temperature control and efficient injection molding

The hot runner system is a key element in improving mold performance. It effectively solves the problem of heat loss of plastic melt in the flow channel in traditional injection molding and maintains the high temperature and good fluidity of the melt. This makes the injection molding process smoother and the product molding more perfect. The hot runner system can accurately control the temperature and pressure of the melt to ensure stable parameters of the plastic when injected into the mold. This is crucial for the production of precision filters. For example, when producing filters with complex internal structures, stable temperature and pressure can ensure that the pores of the filter screen are uniform and the filtration performance meets the design requirements.

Precision filter: the crystallization of high precision and performance

As the final product of the mold, the quality of the precision filter is key. The 12-cavity hot runner mold produces filters with extremely high precision and outstanding performance. Its filter structure is fine and uniform, and the pore size is strictly consistent, which can effectively filter tiny impurities. In the fields of medical, chemical, electronics and other fields, this kind of high-precision filter can play an important role in ensuring the safety of the production process and product quality.

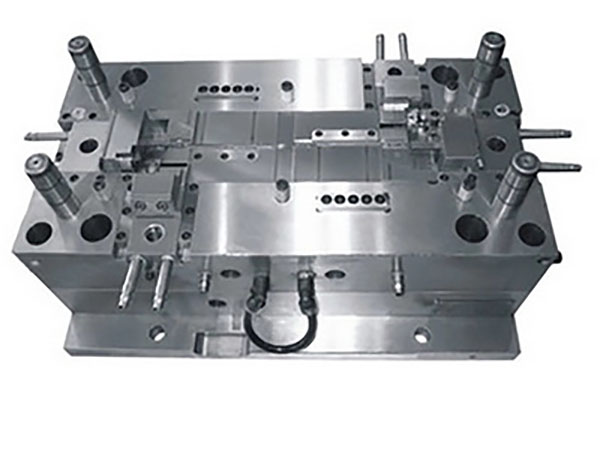

High-precision processing: the cornerstone of quality assurance

In order to achieve high precision and high performance of the mold, advanced processing technology and equipment are used in the manufacturing process. From the mold cavity and core to various minute parts, every link pursues ultimate precision. Through CNC machining, EDM and other processes, the mold's matching accuracy reaches the micron level. This ensures the stability and reliability of the mold in long-term use, producing filters with accurate dimensions and excellent quality.

Good wear resistance: the key to long-lasting and stable operation

Molds will inevitably suffer wear during frequent production. In order to extend the service life of the mold, highly wear-resistant materials and advanced surface treatment technology are used. The surface hardness of the treated mold cavity is significantly improved and it can withstand long-term plastic melt erosion. Moving parts also have good wear resistance, reducing the frequency of breakdowns and repairs.

Efficient cooling: guarantee for improving efficiency and quality

An efficient cooling system has an important impact on mold production efficiency and product quality. Reasonably distributed cooling water channels can quickly and evenly take away the heat during the injection molding process and shorten the product molding cycle. At the same time, uniform cooling helps reduce product internal stress, improve dimensional stability and mechanical properties, and avoid problems such as deformation.

Reasonable design: the core of performance optimization

The overall design rationality of the mold is crucial. From structural layout to runner design to the arrangement of the demoulding mechanism, every detail has been carefully considered. Reasonable design ensures the stability, efficiency and ease of maintenance of the mold during the injection molding process. For example, the optimized exhaust design can discharge gas in time to avoid bubble defects in the product.

Our adavanges

1. Clean and tidy workshop.

2.Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication

Our Services

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or according

to customer's requirement . It takes about 3-5 days to arrive your front

door, and proof of shippments are provided with a shipping or tracking

number. And we ship by occean shippment for larger quantity items,

it will be economic for customers.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang