Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

Precision mold accessories | |

Product Name | Precision mold accessories |

Brand Name | Fair Shine |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

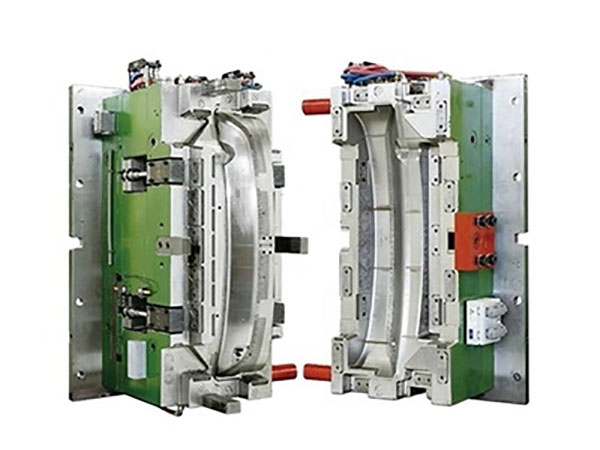

High Light | Medical Precision Mould Parts, S136 Precision Mould Parts, Automotive Injection Plastic Mould |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | HRC48~50 |

Service | Made-to-order |

Application | Equipment Instrument Spare Parts |

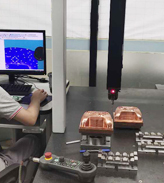

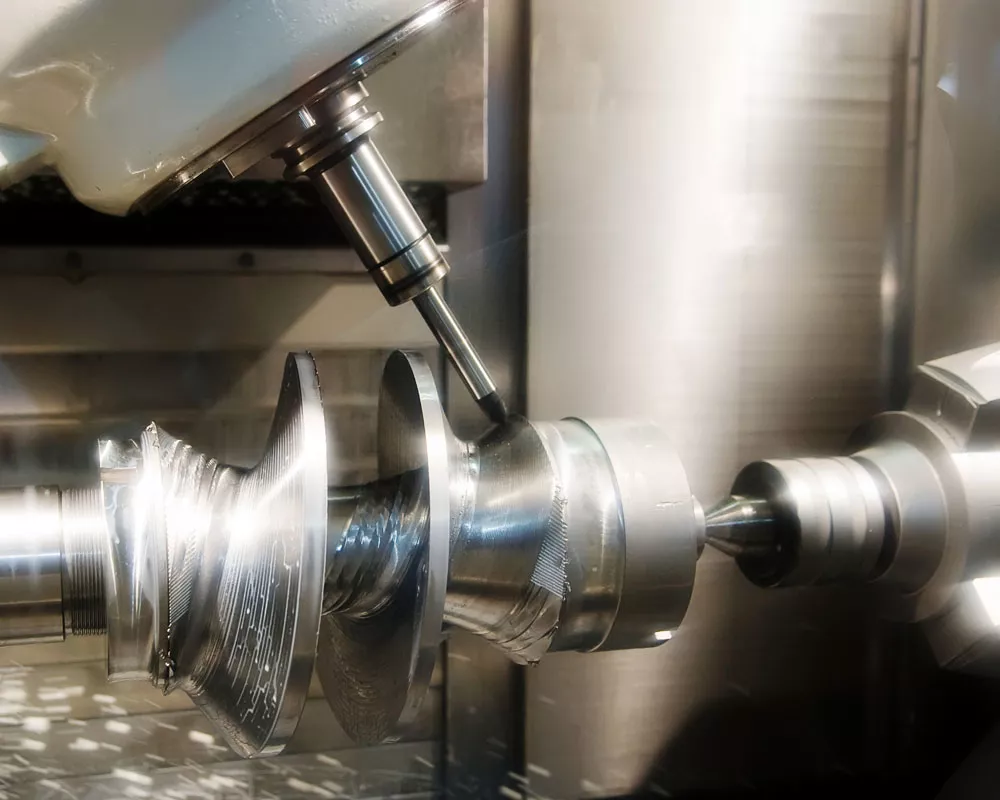

Dongguan Huixiang Mold Technology Co., Ltd. is located in Dongguan, Guangdong. The company uses professional production equipment such as coreless grinders, punch grinders, bore grinders, tooth grinding machines, CNC lathes, deep hole drills, etc. from Taiwan, as well as projectors, two-dimensional dimensional , three-dimensional, height gauge and other precision testing instruments. We have a group of highly skilled mold parts processing talents..

Our products are mainly used in: medical equipment, optical lenses, stationery pens, cosmetic packaging, spray pump molds, automobiles and other plastic hardware mold fields..

Worry about customers' concerns, think about what customers want, and always put customers' interests first!

Stable and precise products, favorable and reasonable prices, fast and convenient delivery, and sincere and responsible service are our pursuit and our commitment to our customers.

1. Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds;

2. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

3. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

4. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

5. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

6 . Guide post guide bushing, GP auxiliary guide post, GP auxiliary guide bushing, SRP ball guide post guide bush, SGP sliding guide post guide bush, discharge plate guide post guide bush, TRP detachable guide post guide bush, independent guide post , non-standard guide posts and bushings and other cold stamping mold accessories;

7. Non-standard customization of SKH51 thimbles, SKD61 thimbles, supporting pins, flat thimbles, shooting pins, cylinder pins, push tubes, imported material thimbles and cylinder cylinders;

8. Guide pins, positioning pins, stoppers Standard and non-standard customization of high columns, limit columns, etc.;

What are the factors that affect the quality of precision mold parts?

There are many factors that affect the quality of precision mold parts, such as the type and quality of the die-casting machine, the rationality of the geometric structure and technical requirements of the die-casting parts, the structure of the mold and the technical level of the operator, etc. When you are confident, you can leave a smaller cutting allowance to extend the life of high-quality precision mold parts tools. Here is a detailed introduction to the factors that affect the quality of precision mold parts?

1. The rationality of accessories design

Designers should first fully understand the user's usage requirements, working conditions, and die-casting force, then select appropriate materials based on the usage requirements and working environment, and understand their material die-casting properties. In the design of precision mold parts, special attention should be paid to the prerequisites of meeting the use requirements and making the die-casting structure as simple as possible. The wall thickness should be appropriately uniform and leave the necessary mold slope, otherwise defects such as pits, pores, shrinkage, under-pressure, stretch marks, cracks, deformation and other defects will occur on the casting. The requirements for dimensional accuracy of castings should be reasonable, otherwise it will bring unnecessary trouble to mold design, mold processing, process condition formulation and management, and result in a large number of unqualified products.

2. Mold structure, processing accuracy and mold material selection

Die-casting is closely related to product quality such as die-casting, mold design, processing, and mold material selection. If the mold structure is unreasonable, no matter what measures are taken in the process of precision mold parts, it will be difficult to make the product qualified. In addition, the mold materials, mold processing accuracy, surface roughness, processing marks, heat treatment small cracks, nitride layer thickness and mold assembly of heat-resistant and wear-resistant precision mold parts will all affect product quality and mold life.

3. Shrinkage rate of accessories materials

The shrinkage rate of the casting material is generally expressed as an average percentage or a percentage of a certain variation range. The average shrinkage rate of the material is usually selected. For the design of high-precision die castings and molds for precision mold parts, special attention should be paid to the selection of material shrinkage. If necessary, you can first test the mold, obtain the required data in the test mold, and then design and manufacture the large mold. Production quantity.

All in all, the formulation and execution of the die-casting process for precision mold parts is related to the quality of the mold, die-casting equipment, and the technical level of the operators. Under the conditions of existing domestic die-casting equipment, it is difficult to achieve stable, reliable and accurate control of the process parameters of precision mold parts. Achieving basic control technology is a process of combining and applying elements such as equipment, materials, and molds.

What are the tips for identifying the pros and cons of mold parts manufacturers?

Based on the strength and scale of the manufacturer. Generally speaking, the mold parts manufacturer's ability to master process technology, the amount and grade of factory equipment, factory area, number of employees, and financial situation can indirectly explain the strength of the mold parts manufacturer to a certain extent. If the mold parts manufacturer has a strong With strong technical strength and large scale, mold parts manufacturers have stricter monitoring of product production processes and quality, and are more capable of producing products with low defective rates.

Based on long-term cooperation with customers of mold parts manufacturers. Understand which well-known merchants the mold parts manufacturers have long-term and stable cooperative relationships with, confirm the type and frequency of cooperation, and appropriately inquire about the basic information of such partners, such as some basic information, popularity in the market, etc. , if the ability and reputation of the partner are confirmed, it can mean that the mold parts manufacturer it cooperates with is also strong in all aspects.

User reviews and reputation. To identify the quality of mold parts manufacturers, users from all walks of life can make judgments about the quality, delivery efficiency, customer service attitude and other related specific evaluations of their mold parts business. Reliable mold parts manufacturers will naturally be able to produce a large number of well-received products. It is a product recognized by the public, and its quality and the manufacturer's service attitude are also highly praised.

It can be seen that reliable mold parts manufacturers can be identified through comparison and analysis of information such as the mold parts manufacturers' technological mastery, financial scale, number of cooperative users, evaluations from relevant customers, and industry reputation rankings. A mold parts manufacturer with strong comprehensive strength in all aspects is not only more capable of producing mold parts with guaranteed quality, but also more capable of providing complete after-sales service to solve users' worries.

How to identify the quality of precision mold base

Precision mold bases play an important role as basic modules in modern production. This kind of customized mold bases are widely used in various light and heavy industrial industries. Therefore, manufacturers focusing on the production of this product have attracted the attention of enterprises from all walks of life, because it can be said that the quality of the mold base directly determines the effect of their production and processing. Therefore, experienced people over the years have summarized a set of instructions on how to identify Non-standard quality methods are introduced one by one below:

First, examine the stability of the product in front-line production

The quality of the precision mold base can first be evaluated from its stability in actual production. You can choose several front-line production areas to examine the status of the mold base, mainly focusing on its fit with the production line and its long-term The status of various aspects after time use. Secondly, understand the specific production process used in the product

You can learn about the various processes used from the mold base manufacturers' introductions and visits. Nowadays, as process technology is becoming more and more developed, the quality of non-standard mold bases has a lot to do with this. Especially when some emerging industries want to introduce mold bases, they should have a good understanding of the process and determine whether the product can meet the requirements of practical applications based on its characteristics.

Then, examine the manufacturer’s quality management standards and implementation effects.

To identify the quality of the mold base, you can also understand the quality management standards used by the manufacturer. Under normal circumstances, the stricter the quality standards and the better the implementation effect, the quality of the mold base can basically be maintained at a higher level. This is why most manufacturers are willing to cooperate with mold base manufacturers who have rigorous forms.

Identifying the quality of the mold base is a reflection of our responsibility for our own production results and quality. The identification methods mainly include inspecting the stability and status of the product on the first-line production line, and inspecting the production process used by the manufacturer to produce it. level, and then examine the quality management standards implemented by the mold base manufacturer and the actual implementation effects.

How to control quality in the manufacturing of precision mold parts

The quality control of the manufacturing of a wide variety of mold parts is closely related to the improvement of product quality. One is the quantity control of ingredients added to make precision mold parts, and the other is the issue of restrictive adjustment of various factors in mold parts. Let’s introduce in detail how to control the quality in the manufacturing of precision mold parts?

The production process must be reasonable

The mold part mixture production process mainly consists of three operations: batching, wet grinding and spray drying. The so-called quality control of mixture production is to effectively control several key parameters of these three operating processes. The quality control of the internal materials of cemented carbide is mainly the control of the total carbon of the alloy, the grain size of the alloy and the internal structure of the alloy. The external quality control of cemented carbide is mainly reflected in the control of the process performance of the mixture, that is, the control of the fluidity and bulk density of the material. The current control focus is on the batching and mixing and grinding processes; the quality control focus of the latter is on the spray drying process.

Cut into uniform sizes and specifications

With the continuous development of science and technology, precision mold parts are gradually developing in the direction of ultra-micro and high precision. In the process of processing precision mold parts, it is often necessary to use corresponding tools to cut the mold parts into shapes with certain dimensions and specifications. , because the mold parts are small in size and require very high precision, in order to meet the requirements of product quality, the precision requirements for their cutting are gradually increasing.

Use high-quality blades during processing and manufacturing

In the existing process of processing mold parts, manufacturers generally use various blades for cutting. Existing blades will cause many problems during the cutting process, and the precision required for producing different mold parts is different. The processing time The amount of displacement will also be different, and the existing blades cannot meet these needs. The control of this part is also relatively strict when it comes to mold parts. All in all, there is no doubt that the mold parts industry requires excellence in the workpieces required by customers. This requires continuous improvement of processes in production, continuous research and development and technical methods to improve workpiece accuracy, overall performance and quality. This is a big challenge for high-quality precision mold parts manufacturers. It is not only the progress of technology but also the progress of technology. Once it can make some progress, its products will have great advantages in the industry.

How to choose precision mold parts manufacturers

As China gradually enters the era of industrialization, the demand for mold accessories from many corporate users is also increasing sharply. Among the many mold manufacturers, how to find a mold parts manufacturer that satisfies users has become a concern for many new users. Through understanding of multiple manufacturers, generally speaking, users who want to choose a good parts mechanism usually need to consider the following aspects: analyze:

Is the service system perfect?

When users choose a manufacturer, they also need to know whether the manufacturer has a complete service system. Usually, the mold parts manufacturers recommended by users have complete services. Users can consult the manufacturers for free. During the consultation process, the customer service staff will provide urgent and considerate answers to the user's questions. , until the user is satisfied. During the purchase process, the professional customer service staff of the mold parts manufacturer will follow up on the delivery progress at any time to ensure that the product reaches the user in time. After the purchase is completed, if the user has any questions, he or she can still consult the manufacturer.

What is the strength of the manufacturer?

To find a good precision mold parts manufacturer, users can investigate the strength of the organization in many aspects, such as whether the manufacturer has advanced CNC machine tools, fully automatic loading machines and other processing equipment, whether it has a professional testing center, and whether the center is equipped with high-end Professional testing equipment, whether it has various mold testing instruments such as salt spray testers, etc., and whether the manufacturer has a professional quality control department, etc. Through this information, users can basically determine whether the organization has certain strength. Only mold parts manufacturers with strong strength can produce high-quality products.

The level of the technical team

When users choose a manufacturer of precision mold parts, they also need to investigate the level of the manufacturer's technical team. Generally speaking, the technical team of a manufacturer with good quality will have comprehensive strength. Not only can the sample manufacturer be able to quickly prototype according to customer suggestions, but also according to the requirements of the prototype. Records and continuous optimization of production processes lay a good foundation for large-scale production. In addition, whether in the sample production stage, product testing stage, or mass production, the technical team can promptly improve product deficiencies according to user requirements. When users need to choose a mold parts manufacturer, only by conducting comprehensive research and analysis on the strength of the manufacturer, the overall level of the R&D technical team, and the service system can we accurately select the mold manufacturer with user satisfaction and excellent quality among the many mold parts manufacturers. In cooperation with this organization, the processing of mold parts was completed smoothly and with high quality and quantity.

Our Services

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

Our adavanges

1. Clean and tidy workshop.

2.Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or according

to customer's requirement . It takes about 3-5 days to arrive your front

door, and proof of shippments are provided with a shipping or tracking

number. And we ship by occean shippment for larger quantity items,

it will be economic for customers.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2025 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang