Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

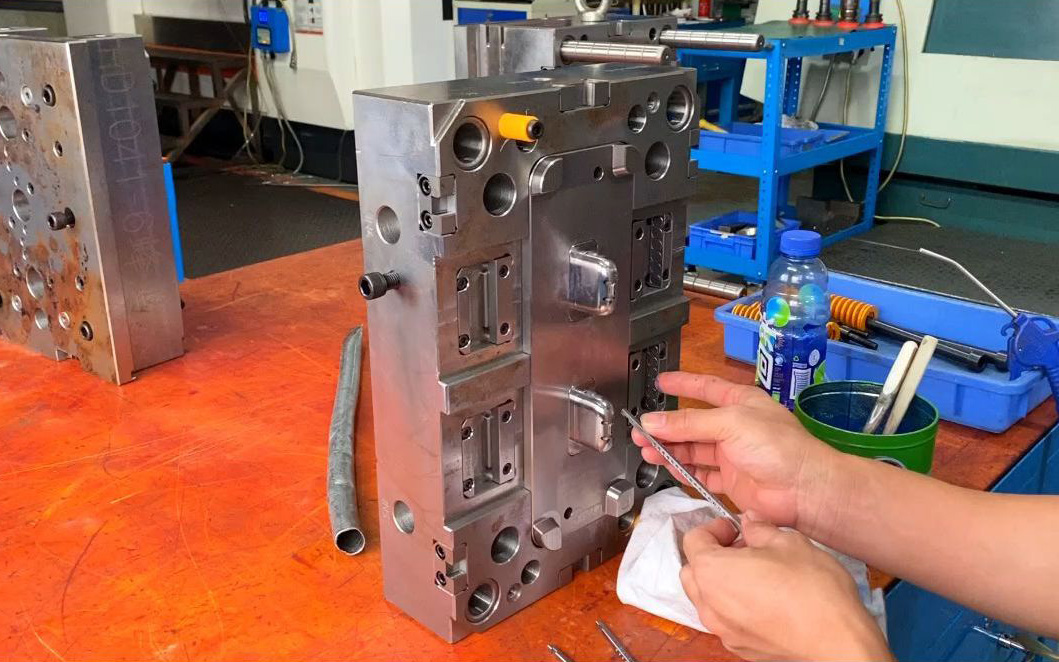

Die casting core die | |

Product Name | Die casting core die |

Brand Name | Fair Shine |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

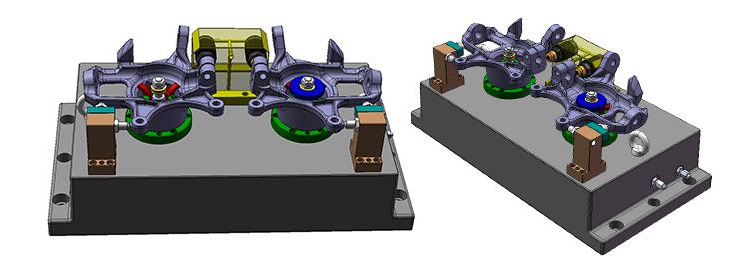

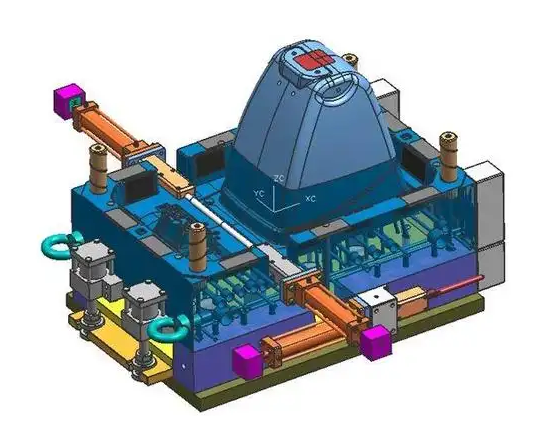

Application | Machinery Parts and Molds |

Dongguan Huixiang Mold Technology Co., Ltd. is a professional manufacturer of cemented carbide series mold accessories. After more than 20 years of continuous practice and innovation, the company has a highly skilled and high-quality technical team.

At the same time, we have also accumulated rich design and manufacturing experience. Main business: cold heading product processing, cold heading mold processing, polycrystalline molds, wire drawing mold processing, water-based hydrogen molds, customized tungsten steel mold punch pins and rods, tungsten steel claws, etc., in order to adapt to the mid-to-high-end markets at home and abroad. In order to meet the demand, the company has recently introduced a series of advanced domestic and foreign molding equipment such as Japan Sodick slow wire cutting machine, fluid polishing machine, Taiwan CNC spark forming machine, Taiwan CNC inner hole grinding machine, and image measuring instrument.

It has laid a solid foundation for Lisong Mold to gain a foothold in the domestic mid-to-high-end market and enter the international market. We firmly believe that as long as we continue to adhere to the business philosophy of "high technology promotes development, high quality survives, and high credibility expands the market", rely on the persevering spirit of innovation, and adhere to the business principles of mutual benefit. Our products will definitely get better and better, and our company will definitely get better and better, and its foundation will last forever. We are willing to work sincerely with domestic and foreign merchants on the basis of mutual benefit and win-win to create a brilliant tomorrow.

1. Pen making/cosmetics/packaging products: pen model refills/pen cap accessories/pen refill thread inserts/lipstick series/spray molds; .

2. Medical packaging equipment products: syringe core/syringe core (combination (pieces)/test tube core/medical packaging bottle cap screw core/drawing cover core and push plate cover; front and rear mold cores such as upper and lower caps of mascara;

3. Optoelectronic/digital electronic products: precision optoelectronic shaft/precision insert Sub/core/busting/precision positioning, etc., the accuracy tolerance is generally controlled within 0.002-0.005, all with test reports for customer inspection;

4. Home appliances, automotive machinery products: self-lubricating wear-resistant blocks (high-strength brass Add graphite)/No oil self-lubricating guide bushing, movable core assembly (inclined top seat)/guide column assistant/positioning column, etc.;

5. Precision stamping mold accessories: non-standard punch needles, punch heads, punch needles, tungsten Steel punch, CNC punch, carbide punch, ASP-23 punch, powder high-speed steel punch, SKH51 punch, SKD11 punch, DC53 punch, double-pin punch, double-pin special-shaped punch, Customized guide punches, guide pins, turning punches, forming punches, elliptical punches, square punches, hexagonal punches, special-shaped punches, etc.;

6. Bushings, die inserts, lower molds, CNC Customized standard and non-standard precision stamping mold accessories such as concave molds, special-shaped bushings, contour sleeves, floating pins, cross pin floating pins, guide lifting pins, tungsten steel punches, etc.;

7. Guide pins, positioning pins, stoppers Standard and non-standard customization of high columns, limit columns, etc.;

8. Drilling die sets, beryllium bronze molds, diamond pins, positioning pins, countersunk hole pins, ejection pins, pins, connecting screws, material blocking shafts, blocking Customized mechanical parts such as material sleeves and bushings;

Introduction to precision mold parts and related processing

Precision mold accessories When it comes to punch needles, we have to explain the stamping mold. The punch needle is an indispensable accessory when the stamping mold is working, and it is a replaceable mold consumable. According to different materials, shapes and uses, punching needles can be divided into SKD, SKH, ASP punching needles, guide punching, mother-and-child punching needles, toothed punching needles, detection pins, hexagonal punching needles, elliptical punching needles, forming punching needles, Sector punches, special-shaped punches, high-speed steel punches, tungsten steel punches, etc. As shown in the figure, various series of punches HL blades are professionally processed: CNC iron tower factory punches, punch mothers, punch rods, punches The nut accuracy remains within ±0.002mm. It adopts Guangshu 980 CNC punch and punch mother professional production workshop. High quality, fast efficiency and other characteristics.

The guide punch needle is also called the guide punch or simply the guide punch. It can have various shapes according to the needs of the stamping machine, including type A, type B, type HB, type TAPP, type TBPP, etc. Zimu punch needle is also called Zimu punch head or Zimu punch for short. There is a small protrusion at the top of the punch. I don’t know where the name comes from. Maybe it’s because of the protrusion at the top of the punch. Letter punching needles can be divided into standard type A type, JSBP type and other models. There are also toothed punches, detection tips, hexagonal punches, elliptical punches, forming punches, fan-shaped punches, special-shaped punches, high-speed steel punches, tungsten steel punches, etc.

Reducing the level of zinc oxide in rubber compounds can reduce rubber mold fouling; the use of nano-sized zinc oxide in precision mold parts can eliminate or reduce mold fouling. However, to achieve optimal mechanical and dynamic performance, more must be done. Research; Other metal oxide catalysts do not solve the mold fouling problem; alternative catalysts, such as amines or mfas, can also reduce mold fouling, however, those catalysts/accelerators have an unpleasant smell and some are toxic of. In addition, in order to obtain a comparable vulcanization speed, an additional zinc catalyst (zbec) must be used.

How to choose mold materials for molds

(1) The mold meets the working conditions requirements

1. Wear resistance When the blank plastically degenerates in the mold cavity, it both flows and slides along the cavity surface, causing severe friction between the cavity surface and the blank, causing the mold to fail due to wear. Therefore, the wear resistance of materials is one of the most basic and important properties of molds. Hardness is the main factor affecting wear resistance. Generally speaking, the higher the hardness of the mold parts, the smaller the wear amount and the better the wear resistance. In addition, wear resistance is also related to the type, quantity, shape, size and distribution of carbides in the material.

2. Most of the working conditions of strong and tough molds are very harsh, and some often bear large impact loads, resulting in brittle fracture. In order to prevent mold parts from suddenly breaking during operation, the mold must have high strength and toughness. The toughness of the mold mainly depends on the carbon content, grain size and organizational state of the material.

3. Fatigue fracture performance During the working process of the mold, fatigue fracture is often caused under the long-term action of cyclic stress. Its forms include small energy multiple impact fatigue fracture, tensile fatigue fracture, contact fatigue fracture and bending fatigue fracture. The fatigue fracture performance of the mold mainly depends on its strength, toughness, hardness, and the content of inclusions in the material.

4. High-temperature performance When the working temperature of the mold is high, the hardness and strength will decrease, leading to early wear or plastic deformation of the mold and failure. Therefore, the mold material should have high anti-tempering stability to ensure that the mold has high hardness and strength at the working temperature.

5. Heat and cold fatigue resistance: Some molds are in a state of repeated heating and cooling during the working process, which causes the surface of the cavity to be subjected to tension and pressure changes, causing surface cracks and peeling, increasing friction, and hindering plastic deformation. Dimensional accuracy is reduced, resulting in mold failure. Hot and cold fatigue is one of the main forms of failure of hot work molds. This type of mold should have high cold and hot fatigue resistance.

6. Corrosion resistance When some molds, such as plastic molds, are in operation, due to the presence of chlorine, fluorine and other elements in the plastic, highly corrosive gases such as HCI and HF are decomposed after heating, eroding the surface of the mold cavity and increasing its surface roughness. , aggravating wear and failure.

(2) The mold meets process performance requirements

The manufacturing of molds generally goes through several processes such as forging, cutting, and heat treatment. In order to ensure the manufacturing quality of the mold and reduce the production cost, its material should have good forgeability, cutting processability, hardenability, hardenability and grindability; it should also have small oxidation, decarburization sensitivity and quenching Tendency to deform and crack.

1. Forgeability has low hot forging deformation resistance, good plasticity, wide forging temperature range, and low tendency of forging cold cracking and network carbide precipitation.

2. Annealing process: The spheroidizing annealing temperature range is wide, the annealing hardness is low and the fluctuation range is small, and the spheroidizing rate is high.

3. Cutting processability: large cutting amount, low tool loss, and low machined surface roughness.

4. Sensitivity to oxidation and decarburization: It has good anti-oxidation properties when heated at high temperatures, has slow decarburization speed, is not sensitive to the heating medium, and has a small tendency to produce pitting.

5. Hardenability: It has uniform and high surface hardness after quenching.

6. Hardenability: After quenching, a deeper hardened layer can be obtained, which can be hardened by using a gentle quenching medium.

7. Quenching deformation and cracking tendency: The volume change of conventional quenching is small, the shape warping and distortion are slight, and the abnormal deformation tendency is low. Conventional quenching has low cracking sensitivity and is not sensitive to quenching temperature and workpiece shape.

8. Grindability: The grinding wheel has relatively little loss, and the limit grinding without burns requires a large amount. It is not sensitive to the quality of the grinding wheel and cooling conditions, and is not prone to wear and grinding cracks.

(3) The mold meets economic requirements

When selecting mold materials, the principle of economy must be considered to reduce manufacturing costs as much as possible. Therefore, on the premise of satisfying the performance, first choose the one with lower price. If you can use carbon steel, you will not need alloy steel. If you can use domestic materials, you will not need imported materials. In addition, the production and supply situation of the market should also be considered when selecting materials. The selected steel types should be as few and concentrated as possible and easy to purchase.

These six requirements when purchasing precision plastic molds cannot be ignored

Plastic mold is the abbreviation of a combined mold used for compression molding, extrusion, injection, blow molding and low foam molding. The coordinated changes of the convex and concave molds and the auxiliary molding system can process a series of plastic parts of different shapes and sizes. In order to meet the needs of molded parts, we need to pay attention to some things when selecting plastic molds and put forward corresponding requirements. The following six requirements need to be met to choose a more suitable plastic mold.

1. High corrosion resistance. Many resins and additives have a corrosive effect on the surface of the mold cavity. This corrosion causes the metal on the surface of the mold cavity to dissolve and peel off, causing the surface condition to deteriorate and the quality of the plastic parts to deteriorate. Therefore, it is best to use corrosion-resistant steel, or perform chromium plating or cymbal nickel treatment on the surface of the cavity.

2. Good wear resistance. The gloss and precision of the surface of plastic parts are directly related to the wear resistance of the surface of the plastic mold cavity. Especially when glass fiber, inorganic fillers and certain pigments are added to some plastics, they Together with the plastic melt, it flows at high speed in the runner and mold cavity, causing great friction on the surface of the mold cavity. If the material is not wear-resistant, it will wear out quickly, causing damage to the quality of the plastic part.

3. Good dimensional stability During plastic molding, the temperature of the plastic mold cavity must reach above 300°C. For this purpose, it is best to use tool steel that has been properly tempered (heat-treated steel). Otherwise, it will cause changes in the microstructure of the material, resulting in changes in the size of the plastic mold.

4. Easy to process Mold parts are mostly made of metal materials, and some have complex structural shapes. In order to shorten the production cycle and improve efficiency, mold materials are required to be easy to process into the shape and accuracy required by the drawings.

5. Good polishing performance Plastic parts usually require good gloss and surface condition, so the roughness of the cavity surface is required to be very small. In this way, the cavity surface must be surface processed, such as polishing, grinding, etc. Therefore, the steel selected should not contain rough impurities and pores.

6. Small impact from heat treatment. In order to improve hardness and wear resistance, plastic molds are generally heat treated, but this treatment should cause very small dimensional changes. Therefore, it is best to use pre-hardened steel that can be machined.

Temperature control of plastic mold processing and injection molding

Temperature control plays a very important part in plastic mold processing and injection molding. It can determine whether the product is good or bad. In the worst case, even if you make it and hand it over to the customer, you will lose the customer's trust in you and cause problems. The company's losses, at most small, don't matter as much as redoing them. You don't need these anymore, but you have to remember that these are actually a waste of the company's resources.

1. Barrel temperature: The temperatures that need to be controlled during the injection molding process include barrel temperature, nozzle temperature and mold temperature, etc. The first two temperatures mainly affect the plasticization and flow of plastics, while the latter temperature mainly affects the flow and cooling of plastics. Each plastic has a different flow temperature. The same plastic has different flow temperatures and decomposition temperatures due to different sources or grades. This is due to different average molecular weights and molecular weight distributions. Plastics in different types of injection molding have different flow temperatures and decomposition temperatures. The plasticizing process in the machine is also different, so the temperature of the barrel is also different.

2. Nozzle temperature: The nozzle temperature is usually slightly lower than the top temperature of the barrel. This is to prevent the "salivation" that may occur in the straight-through nozzle. The nozzle temperature cannot be too low, otherwise it will cause premature solidification of the molten material and block the nozzle*, or the premature solidification material will be injected into the mold cavity and affect the performance of the product.

3. Mold temperature: Mold temperature has a great influence on the intrinsic performance and apparent quality of the product. The mold temperature depends on the crystallinity of the plastic, the size and structure of the product, performance requirements, and other process conditions (melt temperature, injection speed and pressure, molding cycle, etc.).

Our Services

1. Specialized in precision mold part ,inquiries will get highly attention and be prompt response.(within 24 hours).

2. Advanced facilities and experienced engineers, rich experience in mold parts.

3. Guaranteed quality, superior material quality compared to all other.

4. Customer oriented, efficient solution to control the cost for our client.

5. One-stop service, any questions can be solved at the first time by us.

6. Each part has been got 100% inspection before shipment.

Our adavanges

1. Clean and tidy workshop.

2.Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4.Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5.The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package:PE bag with anticorrosive oil,foaming film with carton,or wooden box according to customer's requirement.

Delivery:Delivery time is usually 7-15 working days for type of ejector pin,specific time is according to quantity.

Shipping:We ship using express such as DHL, UPS, FEDEX etc. or according

to customer's requirement . It takes about 3-5 days to arrive your front

door, and proof of shippments are provided with a shipping or tracking

number. And we ship by occean shippment for larger quantity items,

it will be economic for customers.

Fair Shine industrial (Hong Kong) Co., Limited

To provide customers with the most comprehensive precision mold parts solutions.

+86 189 2682 6341

Block 1, No. 12, Wusong 4th Street, Yuwu Industrial Zone, Dongcheng District, Dongguan, Guangdong, China

Copyright © 2026 Dongguan Huixiang Mold Technology Co., Ltd all rights reservrd.

Technical support: HuaShang